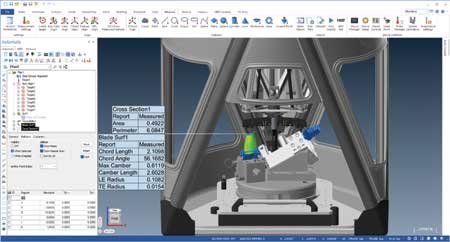

Verisurf Software, Inc. has announced full support for the new Renishaw Equator-X, combining the fast dual-method gauge with Verisurf's CMM Programming & Inspection suite for automated shop floor inspection and reporting. Whether running a small machine shop or a high-rate production line, the new Equator-X with Verisurf offers the speed of a gauge and the precision of a CMM all in one system.

Most manufacturers use Equators as 3D go/no-go gauges. Verisurf takes it further. Using its proprietary Cubic Volumetric Mapping (CVM) process, it error maps and certifies Equator 300 and 500 systems to perform as production-ready CMMs installed on the shop floor, capable of running full inspection routines with traceable accuracy.

Verisurf Software, Inc. has announced full support for the new Renishaw Equator-X, combining the fast dual-method gauge with Verisurf's CMM Programming & Inspection suite for automated shop floor inspection and reporting. Whether running a small machine shop or a high-rate production line, the new Equator-X with Verisurf offers the speed of a gauge and the precision of a CMM all in one system.

"Verisurf supports the new Equator�X as both a gauge and a true CMM, along with the Equator 300 and 500 systems in every compare mode," said Nick Merrell, Executive Vice President at Verisurf. "For over 10 years, Verisurf has optimized the performance of Equator systems using error mapping, enabling them to operate as true CMMs. Equator�X builds on that foundation with increased speed, accuracy and flexibility on the shop floor."

Most manufacturers use Equators as 3D go/no-go gauges. Verisurf takes it further. Using its proprietary Cubic Volumetric Mapping (CVM) process, it error maps and certifies Equator 300 and 500 systems to perform as production-ready CMMs installed on the shop floor, capable of running full inspection routines with traceable accuracy.

Equator-X powered by Verisurf offers:

- High-speed gauging from Renishaw, with traceable inspection, powered by Verisurf

- Dual-mode support, Absolute and Compare, fully automated

- Fast plan creation, repeatable process control and intelligent MBD

- Compatible with all CAD files and 2D drawings

- Device interoperability across Equator�X and traditional CMMs, arms, scanners and trackers

- Unified platform for Renishaw systems, including PH10, PH20, REVO and Equator.

"When you are trying to keep up with high-rate production, you cannot afford to implement solutions that compromise throughput," said Ernie Husted, President and CEO of Verisurf. "Renishaw continues to lead in engineering innovation, and Verisurf translates that innovation into automated inspection workflows built for speed, reliability and production performance."

For more information contact:

Verisurf Software, Inc.

4907 E Landon Dr.

Anaheim, CA 92807

888-713-7201 / 714-970-1683

sales@verisurf.com

www.verisurf.com

Renishaw, Inc.

1001 Wesemann Dr.

West Dundee, IL 60118

847-286-9953

usa@renishaw.com

www.renishaw.com