Tronosjet is using a RenAM 500S to create an engine thrust control pulley bracket conventionally cast from magnesium, a material that suffers from corrosion. The bracket holds a pulley, which redirects engine cables that travel from the cockpit to the pylon connecting the engine to the airframe.

As part of its AM service, Tronosjet designs, prints, heat treats, post-processes and metallurgically tests parts to deliver qualified components along with the required certification data. Its manufacturing facility carries approval as an Aerospace Manufacturing Organization under Transport Canada 561, along with AS9100 approval for design and development. These are industry-recognized standards for quality assurance and risk management for organizations in the aviation sector.

Tronosjet chose to print the engine bracket in aerospace grade Ti-6Al-4V titanium alloy, as opposed to the original magnesium. Its team then conducted extensive NDT, static, functional and destructive testing and compared its performance with the original cast bracket. It found that the printed version was five times stronger, surviving loads over 22,000 lbs., while the original broke at just 4,000 lbs.

According to Jeff Campbell, Director of Maintenance and Manufacturing at Tronosjet, "The thrust control pulley bracket was determined by the FAA to be a Class 1 (critical) part, essential for the safety of the aircraft. We knew that AM could provide the required strength and that having our new bracket certified by the FAA would validate the use of additive in aerospace production."

Renishaw laser powder bed fusion (LPBF) AM systems allow Tronosjet to produce an array of aircraft components, including a safety critical engine thrust control pulley bracket-one of the first additive-produced metallic parts to be certified by the Federal Aviation Administration (FAA) under its Parts Manufacturer Approval (PMA) scheme.

Founded in 2001, Tronosjet is a Canadian aircraft leasing, major modification and aircraft maintenance provider. Historically, the company has owned and managed a fleet of over 60 BAe 146/Avro RJ aircraft, along with engines and spare parts on behalf of third parties. In 2016, the company founded its advanced manufacturing division, established to use additive manufacturing (AM) to produce various aerospace components for its customers.

As part of its AM service, its team designs, prints, heat treats, post-processes and metallurgically tests parts to deliver qualified components along with the required certification data. Its manufacturing facility carries approval as an Aerospace Manufacturing Organization under Transport Canada 561, along with AS9100 approval for design and development. These are industry-recognized standards for quality assurance and risk management for organizations in the aviation sector.

"Although more manufacturers are starting to use AM to produce aerospace components, very few AM parts have received regulatory approval from the FAA-preventing customers from using them on aircraft," noted a spokesperson.

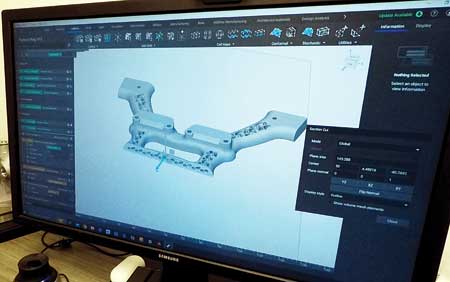

To demonstrate the capability of AM production, Tronosjet selected a BAe 146 part to substitute with an AM version. The part is an engine thrust control pulley bracket, which is conventionally cast from magnesium, a material that suffers from corrosion.

The bracket holds a pulley, which redirects engine cables that travel from the cockpit to the pylon connecting the engine to the airframe. Statically, the bracket is usually loaded with 60-100 lbf of tension from the cable.

"The thrust control pulley bracket was determined by the FAA to be a Class 1 (critical) part, essential for the safety of the aircraft," explained Jeff Campbell, Director of Maintenance and Manufacturing at Tronosjet Manufacturing. "We knew that AM could provide the required strength and that having our new bracket certified by the FAA would validate the use of additive in aerospace production."

With AM still a relatively new technology, Tronosjet knew it would need to demonstrate the quality, strength and reliability of printed parts to the FAA and its regulatory groups, comprised of material scientists, aerospace engineers and other airworthiness specialists.

"Over the years, we have communicated with the FAA many times on different projects, and we understand how it works as a regulatory body," added Campbell. "This gave us an advantage because we knew what to expect. We knew that we would need to prove the bracket's safety using tensile, fatigue and nondestructive testing (NDT), and to show that it would not degrade over time."

As well as proving that the bracket could pass these tests, Tronosjet needed to demonstrate the repeatability of the material and its manufacturing process. Therefore, it required a high-quality AM system that could produce complex metallic components and give the regulators confidence in the company's production team. At this point, it turned to Renishaw.

"Our relationship with Renishaw goes way back-we first went to the UK to meet with its CEO in 2018," said Campbell. "The reason we decided to go for a Renishaw system is the brand. It is highly trusted, and we know it is a company that offers excellent engineering and process capability. The RenAM 500 series are world-class AM machines and of the quality we need to achieve FAA certification. Also, we were impressed with Renishaw's presence across North America, and local support is important for us as a small business taking on new technology."

Renishaw supplied three AM machines to Tronosjet, in both single and multilaser variants, with total loss and recirculating powder schemes. With a build volume of 250 mm x 250 mm x 350 mm and ability to process a range of engineering materials, the systems are ideally suited to a range of Tronosjet's aerospace components. With the flexibility of systems at their disposal, Tronosjet opted to use a single laser strategy and no powder recirculating to produce the thrust control pulley bracket. By maintaining tight control over process variables, Tronosjet was able to address some of the challenges associated with gaining FAA certification for innovative processes.

Tronosjet chose to print the engine bracket in aerospace grade Ti-6Al-4V titanium alloy, as opposed to the original magnesium. Its team then conducted extensive NDT, static, functional and destructive testing and compared its performance with the original cast bracket. It found that the printed version was five times stronger, surviving loads over 22,000 lbs., while the original broke at just 4,000 lbs.

"The numbers put things into perspective," said Campbell. "The bracket's superior tensile strength shows that the titanium print is capable of withstanding significantly higher loads than required when the aircraft is in flight. This helped convince the regulators that AM was more than up to the job."

After Tronosjet demonstrated the part's strength, safety and quality, the engine bracket was certified by the FAA and has received Parts Manufacturer Approval (PMA). Certification demonstrates that the bracket has received adequate testing in line with FAA standards for airworthiness and means that Tronosjet can now produce and supply it to customers. Significantly, it is one of the first FAA PMA certified metallic AM components in the world, giving Tronosjet a competitive edge.

"We are grateful for Renishaw's engineering prowess and support. Its team delivered great products, which have been critical for us achieving certification," concluded Campbell.

For more information contact:

Tronosjet

info@tronosjet.com

www.tronosjet.com

Renishaw, Inc.

1001 Wesemann Dr.

West Dundee, IL 60118

847-286-9953

usa@renishaw.com

www.renishaw.com