5-axis hole deburring with hyperMILL 2025

Linking with hyperMILL Dynamic Stock technology

OPEN MIND Technologies announced it will be demonstrating a range of innovative technology and enhanced features in its hyperMILL 2025 CAD/CAM Software Suite at Manufacturing Technology Series WEST in booth 1537. Productive programming and machining strategies in hyperMILL enable efficient 2.5D, 3D, precision 5-axis and mill/turn machining.

Attendees will learn how the 5-axis automatic tool orientation mode in hyperMILL 2025 offers optimized machining, enabling efficient and reliable tool paths on complex components. The 5-axis automatic tool orientation mode algorithm uses a pre-analysis of the entire tool path to calculate machining sequences of simultaneous and indexed tool movements, reducing the number of inputs required for 5-axis machining and saving time when programming challenging parts.

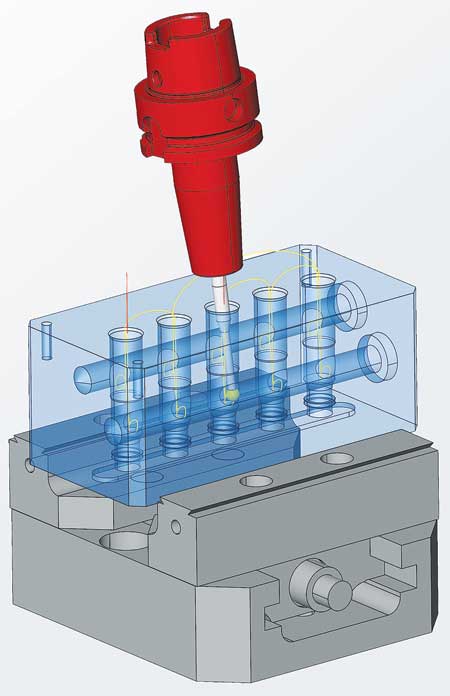

A new 5-axis hole deburring strategy deburrs sharp edges on holes and intersecting holes. By using CAM Plan programming assistance and analysis technology to automatically recognize all the holes, the sharp edges in the model are marked for selecting the desired edges. The hole deburring technology automatically calculates toolpaths and supports 3-axis and 5-axis modes. Also, hyperMILL now offers a 5-axis deburring strategy for fast and efficient deburring of component edges. Users may choose between 3-axis machining and a 5-axis option that enables greater reach to more component edges, automatically generating the required inclinations as well as collision avoidance.

The pocket milling algorithm for high feed cutters in hyperMILL 2025 has been redeveloped for 3D-optimized roughing, achieving greater efficiency during roughing as well as better machining control-especially helpful when machining large lateral in-feeds and remaining material. Contour and path radii can also be defined, resulting in improved toolpath rounding.

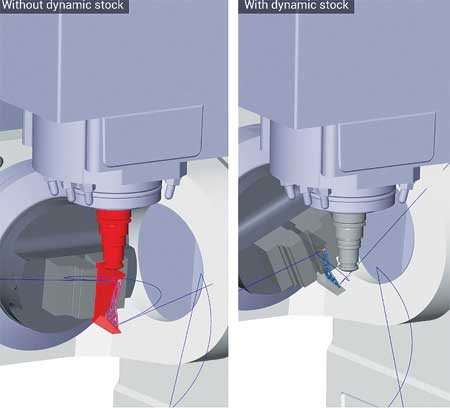

Linking movements via hyperMILL VIRTUAL Machining Optimizer have been further optimized for actual stock conditions with new Dynamic Stock technology. Using Dynamic Stock, an updated stock is automatically generated for all machining jobs and accounted for when calculating linking movements.

For more information contact:

OPEN MIND Technologies USA, Inc.

1492 Highland Ave., Unit 3

Needham, MA 02492

888-516-1232

info.americas@openmind-tech.com

www.openmind-tech.com

MT Series WEST Booth 1537