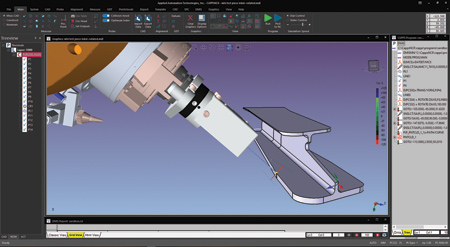

A screen dump of an AAT3D CAPPSNC application that shows a test section of a typical aircraft stringer section.

Applied Automation Technologies (AAT3D) provides on-machine metrology to improve precision manufacturing processes and quality standards by using closed-loop feedback to provide corrections for machining processes that allows the system to be self-adapting to factors that affect the machining processes and the quality of products being machined. Recently, AAT3D was successful in securing a major software contract with a North American aircraft manufacturer that will integrate CAPPSNC software to directly interface with controllers on large CNC machines to provide dimensional metrology data for CMM reports, adaptive work offsets and adaptive tool offsets for 3- to 5-axis closed-loop manufacturing.

Ray Karadayi, AAT3D President and CEO, said, "This CAPPSNC software is truly Factory 4.0 smart manufacturing technology because it is using metrology information throughout the manufacturing process for adaptive control."

Chris Affer, AAT3D Senior Application Engineer, added, "The software provides easy and precise part set-up and machine axis diagnostics. This pre-process approach allows the aircraft manufacturer to set specific work and tool offsets before the machining process. In-process adaptive manufacturing occurs when the software automatically makes machining program corrections with real-time in-process feedback through on-machine probing. Finally, in the post-process, detailed quality reports are created for the machine with SPC analysis and metrology data.

Overall, CAPPSNC is being used for on-machine probing or on-machine 3D scanning. It supports sensor interfaces like CNC touch probes, scanning contact probes, noncontact laser scanners and noncontact CCD cameras. It provides dynamic feedback for errors due to part offsets, errors due to part fixturing, errors due to tool wear and errors due to thermal effects. Ultimately, it can provide all the necessary advanced CMM reporting."

Affer explained further, "CAPPSNC is integrating a wide variety of CNC machines for on-machine inspection and smart manufacturing needs for machining centers, milling and turning machines, turret lathes, large scale 3D printing and additive manufacturing, waterjet and laser cutting machines as well as robotic applications. The most recent aircraft application has been applied at four separate aircraft manufacturing facilities linking 20 different CNC machines, with two additional machines to be added at a later date."

For more information contact:

Applied Automation Technologies, Inc.

1688 Star Batt Dr.

Rochester Hills, MI 48393

248-656-4930

sales@aat3d.com

www.aat3d.com