Zimmermann Displays Three New Machines at IMTS 2022

October 1, 2022

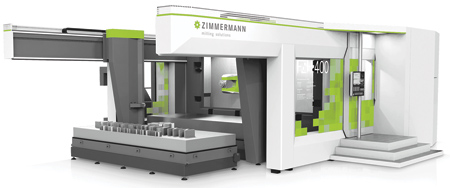

FZH

FZP37

FZU32

FZP42

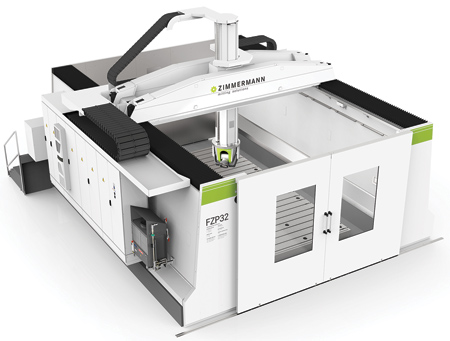

FZP32

FZU37

FZU42

Zimmermann Milling Solutions, a high-tech supplier of portal milling machines, virtually showed three new gantry machines at IMTS.

"When discussing rigidity, nothing beats mass," said a company spokesperson. "Our biggest double bridged gantry sets new standards for dynamic roughing while maintaining high precision. The FZ42 CNC gantry milling machine represents power at its best, combining work areas of different sizes, travels, milling heads and CNC controls. Regardless of weight and size, the milling process is exact. Furthermore, the gantry design is particularly suitable for the entire range of component machining. The structurally rigid center-guiding gantry, cross and Z-Ram, and dynamic milling head enable a consistent, efficient milling process. This combination of high thermal stability and rigidity meets industry-specific requirements in tool and die making, aerospace and automotive industries."

Due to its modular system concept, the FZ37 is available in various sizes, custom configuration and CNC controls. The newly designed gantry with center guided Z-Ram in combination with Zimmermann's dynamic milling heads helps ensure an efficient and consistent milling process. The high thermal stability and rigidity meet industry-specific requirements in model, tool and die making as well as in the aerospace and automotive industries.

The FZ32 is a high-performance solution for dynamic machining of aluminum, fiber composites, plastics and tooling board. Its thermosymmetrical design results in high surface quality and accuracy. The rigid center-guiding gantry allows the company to meet the increasing demands in model and mold making as well as aerospace. Additionally, the flexible design of the FZP machine line offers various sizes and configurations through its modular system as well as extensive equipment options and a fully enclosed work area, including effective dust extraction systems and more.

For more information contact:

Zimmermann Inc.

30587 Century Drive

Wixom, MI 48393

248-305-9707

sales@zimmermann-inc.com

www.zimmermann-inc.com

< back