CSM-1640 lathe

TW-32Qi

KTM-4VKF-E CNC

"Kent Industrial USA offers cost-effective hybrid milling and turning solutions with easy-to-learn conversational programming to empower everyone on the shop floor," said a company spokesperson.

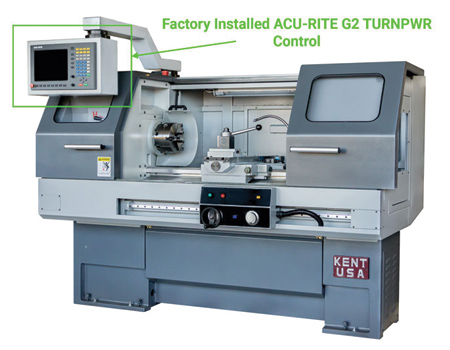

CNC Precision Teach-and-Turn Lathes

CNC teach-and-turn lathes are like regular lathes except they can run in manual mode, full auto or mix and match the two. Kent USA's factory integrated Acu-Rite TURNPWR control on its CSM-1640 lathe is designed to make operation easy.

Features of the CSM-1640 lathe include:

- 7.5 HP frequency drive motor for Acu-Rite TURNPWR (optional is a Fagor CNC control with 7.5 HP Fagor servo spindle motor)

- Manual and CNC mode conversational control

- Rigid Meehanite castings with extra ribbing

- Induction hardened and ground ways

- Gearbox with alloy steel gears that are hardened and ground

- Extra-large precision ground ballscrews

- 50 RPM to 2,000 RPM range; electronic handwheels

- Auto lube system with metered check valves

- Optional automatic four-position electric turret available.

"We make tube sections for the robotic arm for the Mars Mission on our Kent USA CNC CSM-1440 lathe as well as custom match machining for all of the actuators and mechanisms," noted Scott Vanderzyl, Principal Manufacturing Engineer, Motiv Space Systems.

CNC Milling Machines

"The Kent USA CNC milling machines are designed for ease of use, machining flexibility and reliable performance," said the spokesperson. "They are well-suited for tool rooms and job shops, from prototyping or one-offs to small and medium production runs. In addition, they are engineered for virtually every industry application, from R&D vertical machining to production shops."

Bed-type milling machines, like the TW-32Qi, are capable of taking heavy cuts, such as making mold bases.

Features of the TW-32Qi:

- 12" x 50" working capacity (larger sizes available)

- 32" x 18.5" x 18.5" XYZ travels

- 20" spindle center to column

- 1,000 lbs. max. workload

- 7.5 HP spindle motor

- Powered by Acu-Rite G2, FANUC or other controls upon request.

"Knee-type milling machines, like the KTM-4VKF-E CNC, bring powerful CNC capabilities to the tool room with easy-to-learn conversational programming and advanced canned cycles to empower everyone on the shop floor for greater productivity," said the spokesperson.

Features of the KTM-4VKF-E CNC:

- 9" x 49" to 12" x 50" working capacity

- 31" x 11" x 15" to 33" x 18" x 18" XYZ travels

- 850 lbs. max. workload

- AC frequency drive head 60-550-4,500 RPM

- Up to 5 HP spindle motor

- Powered by ACU-RITE G2.

For more information contact:

Kent Industrial USA

1231 Edinger Ave.

Tustin, CA 92780

800-KENT-USA / 714-258-8526

sales@kentusa.com

www.kentusa.com