Nidec Machine Tool Corporation has launched the MVR-Ax series of double-column machining centers.

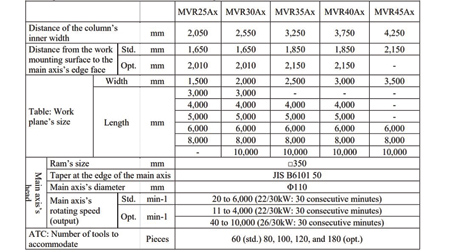

The main specifications of the double-column machining centers in the MVR-Ax series.

Nidec Machine Tool Corporation (led by Kenichi Wakabayashi, President, and headquartered in the city of Ritto, Shiga Prefecture, Japan) announced that it has launched the MVR-Ax series of double-column machining centers.

These new products were developed as easy-to-use machines to meet the diverse needs of manufacturing sites that machine large-size components. Together with their predecessors-high-end model MVR-Hx and standard model MVR-Cx (intended mainly for mid-size workpieces), both launched last October-the MVR-Ax series can use a large number of options. These range from a table size that can accommodate large-size workpieces to a variety of attachments to the main axis to automated functions such as a palette changer. In addition, the high-performance grinding technology and the digital technology to improve operability and maintenance capability enhance the MVR-Ax machining centers' overall productivity.

The machining centers in the MVR-Ax series are equipped with a main axis that rotates at a standard speed of 6,000 RPM to machine large-size workpieces such as industrial, construction, semiconductor manufacturing and power-generating equipment, and with a gear drive main axis (opt.) (4,000 RPM, with a maximum torque of 3,430 N�m) for deeper cutting operations. Combined with resilient structures of their main unit, which remain completely undamaged from this high torque, the products have sturdy ram main axes that enhance the cutting capability during ram protrusion, while enhancing the performance of the machining of tall components' lateral sides.

A number of attachments enable the machining centers of the MVR-Ax series to machine objects of various shapes, including narrow sections, multifaceted surfaces, slant planes and adjustable surfaces. Furthermore, the individual axes' fast-forwarding speeds are 30 m/min. for the X-axis, 32 m/min. for the Y-axis, 20 m/min. for the Z-axis and 5 m/min. for the W-axis. The shortened noncutting time makes the MVR-Ax series highly productive.

The MVR-Ax series features NidecNavi, an operational assistance function to help the operator create NC programs and perform centering work efficiently, and a collision prevention function to prevent tool-work collision. DIASCOPE, the company's IoT platform, provides swift and secure support for the MVR-Ax series. Additional features include technologies to enhance their environmental performance, an idling stop function for the oil cooler and the hydraulic unit to reduce electricity consumption and serve other energy-conserving purposes.

For more information contact:

Nidec Machine Tool America LLC

46992 Liberty Drive

Wixom, MI 48393

248-669-6136

www.nidec.com