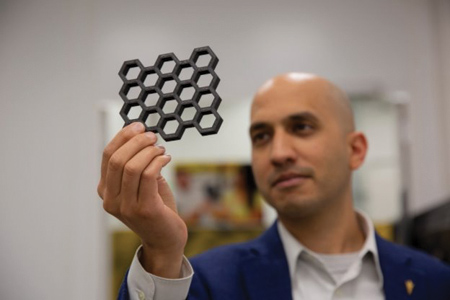

Dhruv Bhate is an Associate Professor at Arizona State University in the School of Manufacturing Systems and Networks, where his research group, 3DX Research, studies design and mechanics of additive manufacturing structures and materials. Photo by Erika Gronek/ASU

Engineering major Jean-Francois Enriquez uses Siemens hardware to operate a digital twin machine as part of his senior design capstone project. Photo by Sona Srinarayana/ASU

Manufacturing is ubiquitous in modern life. Our computers, our cars and many of the products we use daily are created using advanced manufacturing systems. To meet the future needs of manufacturing in a high-tech world, existing manufacturing systems must evolve and new ones need to emerge.

This is why the Ira A. Fulton Schools of Engineering at Arizona State University (ASU) launched the School of Manufacturing Systems and Networks last fall.

The School of Manufacturing Systems and Networks, the seventh school in the Fulton Schools of Engineering, will integrate academic programs and innovative research to address current and future challenges, improve sustainability and generate economic opportunities to revitalize manufacturing in Arizona and beyond. And the school will play a significant role in supplying the skilled talent needed to support U.S. efforts to re-establish its leadership in advanced manufacturing.

These factors to enhance ASU's impact on Industry 4.0 are catalyzed by the growth and transdisciplinary knowledge generation happening in the Fulton Schools. As one of the country's largest and most comprehensive engineering schools, the Fulton Schools is well-positioned to lead industry-relevant research and technology innovation in the processes and systems that will drive the future of manufacturing.

"ASU's record of innovation and leadership in engineering education puts us at the center of a national effort to accelerate advanced manufacturing and, in turn, to substantially improve competitiveness and agile innovation for a myriad of critical industries. This includes semiconductors and microelectronics, two areas we read about essentially every day and are vital to national security," said Kyle Squires, ASU Vice Provost for Engineering, Computing and Technology and Dean of the Fulton Schools. "The School of Manufacturing Systems and Networks is the embodiment of ASU's commitment to use-inspired research and educating students for a technologically enhanced future of work."

Preparing Students for Factories of the Future

The School of Manufacturing Systems and Networks is building upon existing manufacturing and systems engineering programs at The Polytechnic School-one of the seven Fulton Schools of Engineering-and strategically centering its curriculum, research portfolio and industry engagements to meet the growing demands of an evolving manufacturing landscape.

"If you look across the country, there are more than 2 million manufacturing jobs that could go unfilled, and this particular school is trying to fill that workforce gap," said Binil Starly, the inaugural Director of the School of Manufacturing Systems and Networks.

Starly joins ASU after nine years as a North Carolina State University professor. There, he led the Data Intensive Manufacturing Environment Lab, or DIME, where he merged digital and physical technologies to advance discrete and continuous manufacturing processes.

Associate Professor Dhruv Bhate has a heightened awareness of the looming manufacturing job deficit from his experiences as a faculty member in The Polytechnic School and prior engineering industry roles at Intel Corporation and PADT, Inc.

"As we look forward and imagine the future of manufacturing, we have the opportunity to shape it in a more responsible way to advance humankind like never before," said Bhate, who now teaches in the School of Manufacturing Systems and Networks.

Bhate said that traditionally, when companies hire engineers to fill manufacturing positions, the pool is limited to mechanical engineers, industrial engineers, material scientists or chemical engineers because they are not able to readily find candidates who possess a wide breadth of manufacturing relevant engineering skills.

"Addressing the next generation of manufacturing challenges and opportunities are multidisciplinary and include process science and engineering, robotics and automation, as well as data analytics, cybersecurity and artificial intelligence (AI)," Bhate said. "These are the areas a manufacturing graduate of the future will be required to have familiarity with when they enter the workforce."

To address this talent gap, students in the School of Manufacturing Systems and Networks will have access to opportunities to develop their skills in modeling, automation, sensing, advancing manufacturing processes, robotics, human-machine teaming, machine learning, data optimization and digital twin systems, among other areas.

Keng Hsu, an Associate Professor for the School of Manufacturing Systems and Networks, believes that "this new approach of combining disciplines will create a manufacturing educational enterprise that is different from most in the country."

Integrating existing engineering and technology programs on the Polytechnic campus with the new manufacturing-related programs in the School of Manufacturing Systems and Networks is enabling a surge of cross-program collaboration that will further contribute to the school's goal.

The Polytechnic campus is already home to the robotics and autonomous systems program, the information technology program and the human systems engineering program, which focuses on how humans engage with new technologies.

The software engineering program, part of the School of Computing and Augmented Intelligence-another one of the Fulton Schools-is also on the Polytechnic campus. Software engineering, an area Starly said "is driving new manufacturing information technology," will equip students with the information systems knowledge required to advance AI on the factory floor.

"I am excited because we have everything we need to make an impact right here on the Polytechnic campus," said Thomas Sugar, a President's Professor in the School of Manufacturing Systems and Networks and the Associate Dean of Barrett, The Honors College at ASU's Polytechnic campus.

Sugar looks forward to working with faculty members who are bringing new skill sets to the Fulton Schools of Engineering. "ASU is investing in professors that are experts in Industry 4.0," he said. "This is crucial when building an advanced manufacturing ecosystem in Arizona where the Fulton Schools of Engineering will become the largest technical producer of talent in the U.S. The process will eventually become a robust economic engine."

A group of The Polytechnic School's faculty will transition to the School of Manufacturing Systems and Networks, many of whom have had distinguished industry careers. Of that group, five are recipients of the National Science Foundation Faculty Early Career Development Program (CAREER) Award. Many also have solid entrepreneurial roots, holding patents and having launched startup companies to translate their research to use.

"This faculty group has a strong collaborative nature and they will bring that mindset with them," said Ann McKenna, Vice Dean of Strategic Advancement for the Fulton Schools. "They all enable technology being put to immediate use."

The School of Manufacturing Systems and Engineering will also play a critical role in ASU's ongoing effort to strengthen workforce readiness and stimulate economic growth in Arizona. Interested students can conduct research in one of ASU's five new Science and Technology Centers, or STCs.

These centers, supported partly by Arizona's New Economy Initiative, represent a strategic collaborative effort by Arizona universities, state government and industry to accelerate talent and skills development in key areas driving industrial growth and strengthening the state's economic development.

Hsu said that the Manufacturing, Automation and Data Engineering STC-with its focus on creating and optimizing advanced manufacturing technologies-will promote industry-driven manufacturing research and help solve industry-scale technical problems.

"This is a meaningful way of generating data and generating impact," Hsu said, "and was one of the many reasons I decided to join the new school."

The presence of new and existing Valley manufacturers investing in next-level technologies is spurring opportunities for ASU and the Arizona workforce.

With plans to begin production in 2024, TSMC, a semiconductor manufacturer, is investing $12 billion in a chip-making plant in North Phoenix. Intel Corporation and NXP Semiconductors, companies with strong roots in the Valley, have plans to expand their presence in Phoenix.

Additionally, a growing electric vehicle industry, including Lucid Motors, Atlis Motor Vehicles, ElectraMeccanica and Nikola Motor, is adding to the abundance of prospective career options for Fulton Schools students.

"The multiplier effect for manufacturing jobs is another important factor to look at," Sugar said. "One manufacturing job brings nine additional jobs."

Industry-Centric Environments Provide Authentic Learning Opportunities

Located on ASU's Polytechnic campus, the School of Manufacturing Systems and Networks leans into The Polytechnic School's already established project-based and hands-on learning pedagogy.

Seasoned collaborations with some of Arizona's top manufacturing employers like Rockwell Automation, PADT, Inc, Honeywell Aerospace, Pilgrim Aerospace Fasteners, Siemens, Raytheon Missiles and Defense, TPI Composites, Lallemand Baking and others will help foster the new school's industry-forward mindset.

"As an industry, we are trying to put the most advanced manufacturing technology in the hands of ASU students as soon as possible," said Michael Cook, Director of Global Academic Enablement at Rockwell Automation. "In many institutions, there is a lag between when students adopt technologies and when they get integrated into the curriculum. The goal is to integrate the most current technologies so that program participants will graduate with the skills needed to meet the demands of the workplace."

Rockwell Automation provides automation solutions to American companies, many of which are in Arizona.

"We believe in working with impactful, highly-recognized and accredited programs with industry collaborative faculty, so there was not a second thought when deciding to partner with the Fulton Schools," Cook said.

Eric Miller, Principal and co-owner of PADT, Inc, a provider of numerical simulation, product development and 3D printing products and services in Tempe, agrees that the ease of working with The Polytechnic School's faculty and being able to hire students with a practical background to immediately add value to their organization was the initial attraction to working with ASU. As PADT, Inc joins forces with the School of Manufacturing Systems and Networks, Miller said their breadth of impact will expand.

"Our needs lie within advanced manufacturing, and we see every aspect of the new school as very important to attracting companies that will become our customers," Miller said. "So the better the reputation and the better quality of students that this new school creates, the more customers, in the long run, we will have."

Doug Bingham, Senior Director of Advanced Manufacturing Technology at Honeywell Aerospace, sees Honeywell's relationship with the university as an investment in the company's talent pipeline.

"When students join Honeywell, we want to give them the tools they need to make an immediate impact, and this is where I see us-together with ASU-unlocking value," Bingham said. "I have an intrinsic belief that there is something greater here than just recruitment and hiring. If a curriculum supports all the disciplines needed for the projected manufacturing landscape, very powerful opportunities can be created."

A Foundation Built for Greatness

The School of Manufacturing Systems and Networks has a critical responsibility in the grand scheme of Arizona's flourishing manufacturing industry, and it is poised to take on the challenge.

From innovative and iterative course offerings taught by esteemed faculty to substantial industry engagement and a thriving manufacturing job market, the key elements for the success of ASU's newest engineering school are all in place. Separately, these elements are robust, but the synergy formed as they meld will generate boundless opportunities for students and faculty, industry and the state of Arizona.

"My goal is to deliver on the vision," Starly said. "I am looking forward to taking this school that is in its initial stages and laying the groundwork so it has the foundation to grow at scale over the course of the next five to 10 years."

Authored by Sona Srinarayana, Communications Specialist, ASU

For more information contact:

Ira A. Fulton Schools of Engineering

Arizona State University

7111 E Tiburon Ave.

Mesa, AZ

855-278-5080

engineering.asu.edu