New Model MELD Machine Announced

March 1, 2021

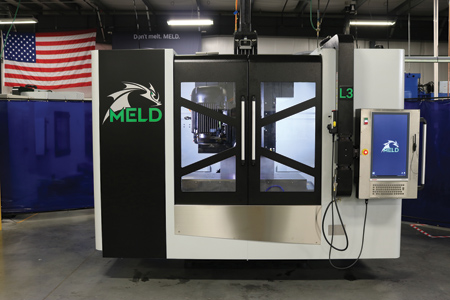

The L3 offers a generous workspace and build volume.

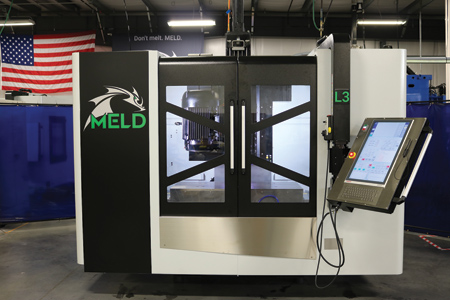

L3 swivel operator panel offers flexibility of use.

Director of Technology Dr. Chase Cox inspects the spacious L3 work area.

A new machine model was recently announced by MELD Manufacturing Corporation. "The L3 model MELD machine combines the modern aesthetics and features of the larger MELD K2 model at a reduced size and price point that may be more attractive to customers looking to enhance or expand their metal printing portfolio," said a company spokesperson.

The L3 machine has a build volume of 6.75 cubic feet (2.06 cubic meters) with a table size for fixturing parts that measures 51" x 23" (129.5 cm x 58.4 cm). The L3 complements the product line that includes the B8 model with a 3 cubic foot build volume and the K2 machine with an 82 cubic foot build volume.

"The open-air operation of the additive manufacturing (AM) machine makes it unique in simplified requirements for material, usability and operating costs. This simplicity extends to safety, only requiring standard manufacturing protective equipment," said the spokesperson.

The L3 model machine is the third product brought to market by the woman-owned business, still only in its third year as a company. "When we looked at our customers and what they wanted to do with the technology, it was clear that there needed to be a machine with a platform perfect for both part fabrication and repair. The L3 serves that need, offering a tremendous increase in production capability without requiring a larger footprint on the manufacturing floor," stated MELD Manufacturing Corporation Director of Technology Dr. Chase Cox.

For more information contact:

MELD Manufacturing

200 Technology Drive

Christiansburg, VA 24073

540-951-3980

websales@meldmanufacturing.com

www.meldmanufacturing.com

< back