Inkjet Marking System for Improved Part Accuracy

March 1, 2021

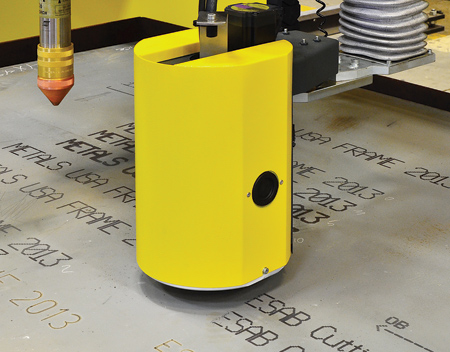

ESAB's inkjet station, an option for any of its cutting automation systems, is designed to improve marking accuracy, safety and productivity.

ESAB Welding & Cutting Products has introduced an inkjet plate marking tool, an option for any ESAB cutting automation system. With options that include fixed or rotating heads, as well as Drop On Demand or Continuous Inkjet technology, the inkjet station is suitable for steel service centers, shipyards and manufacturers that require traceability of their parts within the production environment. "Inkjet marking especially appeals to manufacturers who want to identify parts during assembly but then want to shot blast or paint over the marks on the finished product," said a company spokesperson.

"Adding an inkjet marking station to an automated cutting table reduces cycle time because the system can mark parts much faster, with less error and in much greater detail than a human operator working by hand," said Steve Zlotnicki, Global Product Manager, ESAB Cutting Systems. "Automated marking also eliminates the potential hazard of operators climbing on the table or trying to mark parts while the system is cutting."

ESAB offers two types of inkjet technology from which to choose. Drop On Demand (DOD) prints characters up to 67 mm tall for greater visibility. Continuous Inkjet (CIJ) uses dual-nozzle technology for the higher definition required by bar codes, QR codes or data matrix codes. CIJ can print characters up to 20 mm tall. Both types of systems can be used for marking either text or layout lines, and text can be oriented in any direction using an automatic rotation system.

For more information contact:

ESAB Welding & Cutting Products

256 Midway Drive

Union, SC 29379

800-ESAB-123 / 864-466-0921

www.esabna.com

< back