Large Format 3D Metal Printer

March 1, 2021

VELO3D's new Sapphire XC, an "Extra Capacity" large-format printer, is designed to increase production throughput by 5x and reduce cost per part by up to 75%.

VELO3D has announced the expansion of its systems portfolio to include Sapphire XC, an "Extra Capacity" large-format printer designed to increase production throughput by 5x and reduce cost per part by up to 75%, when compared to the existing Sapphire system.

The company also rolled out Sapphire Gen 2, which is a software and hardware upgrade to the current system. Users can expect an improvement of anywhere between 10-50% in productivity and part-cost metrics when compared to the current Sapphire system, according to the company.

The Sapphire product family now includes Sapphire Gen 2, the 1 m tall Sapphire 1MZ and Sapphire XC, all using the laser powder-bed fusion (LPBF) process with patented capabilities to print without consideration of support structures. Sapphire systems are designed for the aerospace, power generation and energy markets.

"Printing larger parts without the additive manufacturing (AM) constraints of support structures is highly attractive to many industrial end users," said Benny Buller, founder and CEO of VELO3D. "For the first time, customers will be able to 3D print uncompromised geometries, with the highest confidence in part quality, in a large format system. Quality assurance with large scale components is critical because the economic impact of failed builds is very significant. We have demonstrated that our integrated solution is capable of producing a greater yield of high-quality parts, and that foundational technology will transfer to our new Sapphire XC."

Sapphire XC features:

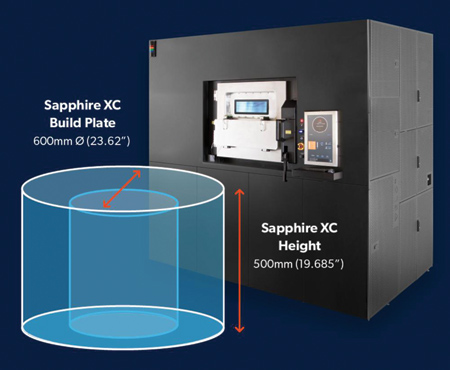

- Larger build volume of 600 mm x 550 mm (compared to 315 mm x 400 mm in Sapphire)

- Eight lasers x 1,000W each (compared to two lasers x 1,000W in Sapphire)

- Fully integrated with Flow pre-print software and Assure quality control software

- Utilizes the same optical-train design, recoater technology, gas flow technology and metrology as the current Sapphire. Users can also expect similar material properties as Sapphire

- Compatible alloys include Aluminum F357, Titanium 6AI-4V, Inconel 718 and Hastelloy X.

Delivery of Sapphire XC will begin in Q4 2021.

For more information contact:

Velo3D

511 Division St.

Campbell, CA 95008

408-610-3915

www.velo3D.com

< back