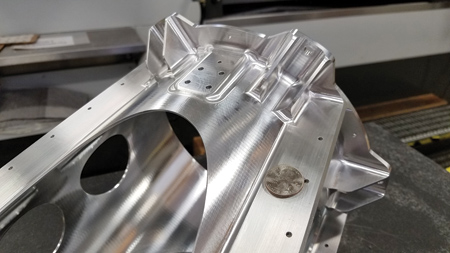

hyperMILL MAXX Machining finishing module enables large step-overs for barrel cutter paths when finishing this aerospace part.

OPEN MIND Technologies AG, a developer of CAD/CAM software solutions worldwide, reported that its customer Concept Reality Inc. is increasing productivity and improving part accuracy using the hyperMILL MAXX Machining finishing module for aerospace part manufacture.

hyperMILL CAM software from OPEN MIND enables enhanced 5-axis strategies for fast, easy-to-use programming, resulting in reduced cycle times and high quality surface finishes. The integrated hyperMILL MAXX Machining finishing module, a performance package of the hyperMILL CAM software suite, is the CAM programming source enabling the use of conical barrel cutter technology to reduce cycle times over 90%. It is suitable for planar, ruled and curved surfaces often found in complex 5-axis components. hyperMILL MAXX Machining offers three modules for finishing, roughing and drilling.

"On a recent aerospace project, the hyperMILL MAXX Machining finishing process allowed us to increase our step down between toolpaths by 12x when compared with traditional machining methods using ball nose cutting tools. This saved us 5 hours per part in finishing operations while reducing cusp height," said Chris Nunn, President of Concept Reality Inc. "We were able to deliver a higher quality part in less time - a great benefit to our customer."

The hyperMILL MAXX Machining finishing module makes efficient use of machine and tool options in relation to surface quality and speed, by applying an innovative 5-axis tangent plane machining strategy and conical barrel cutters that use the functions of a barrel cutter and a ball mill simultaneously.

A conical barrel cutter features a large radius - ranging from 250 mm to 1,500 mm. The large radius of the conical barrel cutter makes step-over distances of 6 mm and 8 mm a reality. It does not require switching cutters in order to finish adjacent areas such as rounded interior corners, and hard-to-reach areas can be machined in a highly efficient, secure manner. In addition to enhanced surface quality, the hyperMILL MAXX Machining finishing process enables short production times, increased tool life, the use of fewer tools and a high degree of process reliability.

For more information contact:

OPEN MIND Technologies USA, Inc.

1492 Highland Ave., Unit 3

Needham, MA 02492

888-516-1232

info.americas@openmind-tech.com

www.openmind-tech.com