In OP 10 and OP 20, the VL 3 DUO dual-spindle vertical turning center is used to machine both sides of the gear blanks.

The pick-up automation system integrated into each modular machine features a parts storage unit for blanks and finished parts.

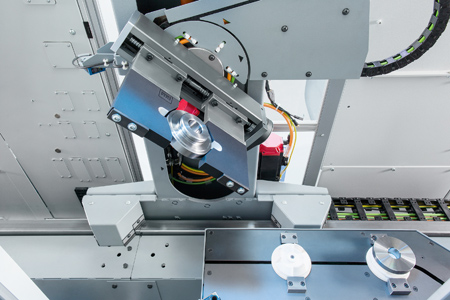

The gear hobbing unit by EMAG provides for high torques and a fast gearing process.

The TrackMotion automation system ensures smooth parts transportation, and allows the use of stackers for space-saving depositing of finished sprockets.

"We have separated the machining process for gears into four easily manageable sub-processes," said Peter Loetzner, President and CEO at EMAG L.L.C. "In OP 10 and OP 20, we use the VL 3 DUO dual-spindle vertical turning center to machine both sides of the gear blanks. In OP 30, we do the gear hobbing on our VL 4 H gear hobbing machine. The final chamfering and deburring of the finished gear in OP 40 is done on our VL 2 RC or VL 2 CC, depending on what technology is used, Chamfer-Cut or Roll Chamfering.

Clever Automation Solution

The pick-up automation system integrated into each modular machine features a parts storage unit for blanks and finished parts, from which the machine is automatically loaded. With this system, the machine can achieve short chip-to-chip times of only a few seconds. "The vertical construction of the machine not only guarantees an ideal chip flow, but also prevents the formation of chip clusters, contributing to a consistently high quality of production," said a company spokesperson.

The interlinking of machines is easy to implement due to the consistent transfer height between the automation systems of individual machines. In addition, the separate energy cabinet allows the use of the new EMAG TrackMotion automation system specially developed for modular machines. The automation system, located directly behind the machining area, transports the parts and also operates as a flip-over unit, which increases the flexibility of the entire system.

For more information contact:

Kirk Stewart

Sales Director

EMAG L.L.C.

38800 Grand River Ave.

Farmington Hills, MI 48335

248-996-4703

kstewart@emag.com

www.emag.com

SOUTHWEST

TX, OK, AR, LA

Eric Klenner

Regional Sales Manager

EMAG L.L.C.

248-595-1530

eklenner@emag.com

NM

Shane Cross

Regional Sales Manager

EMAG L.L.C.

248-207-5365

scross@emag.com

SOUTHEAST

MS

Eric Klenner

Regional Sales Manager

EMAG L.L.C.

248-595-1530

eklenner@emag.com

AL, GA, FL, NC, SC, E. TN, VA

Dave Fitzgerald

Regional Sales Manager

EMAG L.L.C.

248-595-1117

dfitzgerald@emag.com

W. TN

Mark Comeaux

Regional Sales Manager

EMAG L.L.C.

248-938-2097

mcomeaux@emag.com

NORTHEAST

W. PA, WV

Mark Comeaux

Regional Sales Manager

EMAG L.L.C.

248-938-2097

mcomeaux@emag.com

NY, PA, DE, MD, NJ, CT, RI, MA, VT, NH, ME

Kevin Gadde

EMAG L.L.C.

248-938-2430

kgadde@emag.com

Portions of NY and PA

Jeff Moore

Regional Sales Manager

EMAG L.L.C.

519-835-8425

jmoore@emag.com

MIDWEST

OH, KY, IN

Mark Comeaux

Regional Sales Manager

EMAG L.L.C.

248-938-2097

mcomeaux@emag.com

W. MI

Peter Vandersluis

Regional Sales Manager

EMAG L.L.C.

616-307-7401

pvandersluis@emag.com

E. MI

Mark Ashworth

EMAG L.L.C.

248-826-4242

mashworth@emag.com

ND, SD, NE, KS, MN, IA, MO

Bill Konetski

Regional Sales Manager

EMAG L.L.C.

612-804-0857

bkonetski@emag.com

IL, WI

Joe Thompson

Regional Sales Manager

EMAG L.L.C.

248-880-0233

jthompson@emag.com

WEST

WA, OR, CA, NV, ID, MT, WY, UT, CO, AZ

Shane Cross, CMTSE

EMAG L.L.C.

248-207-5365

scross@emag.com