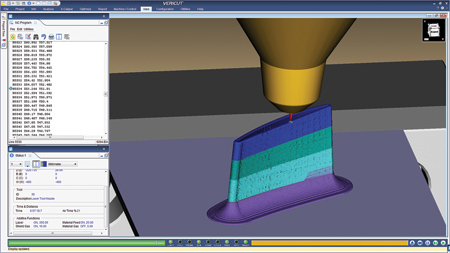

VERICUT's Additive capability verifies laser function, detects collisions and checks material deposition. Simulation is powered by the same NC code that drives the hybrid CNC machine.

CGTech has announced the next major release of VERICUT software. VERICUT CNC machine simulation, verification and optimization software simulates all types of CNC machining, additive and hybrid manufacturing processes. The software operates independently, but can also be integrated with leading CAM systems.

"VERICUT 8.1 includes many enhancements that simplify simulating a CNC machine," said VERICUT Product Manager Gene Granata. "This release is all about various tools that can increase NC programmer efficiency, reduce production time and detect costly errors before going to the shop floor."

New modules have been added including: Additive, Grinder-Dressing and Teamcenter Interface. Many enhancements improve VERICUT's core functionality such as: easier sectioning that extends to machine views, X-Caliper dimension labels displayed with models, new report template editor and easier G-code offsets. Many customer-driven enhancements and software change requests were also completed.

New Module: Additive

VERICUT's Additive module simulates both additive and traditional CNC machining capabilities applied in any order. Simulating both operations identifies potential problems that can occur when integrating additive methods. The user has access to detailed history stored with VERICUT's unique droplet technology, which saves programmers time by quickly identifying the source of errors with a single click. This additive capability shows realistic laser cladding and material deposition, detects collisions between the machine and additive part, and finds errors, voids and misplaced material. VERICUT simulates the post-processed NC code that controls the CNC machine ensuring proper usage of Additive functions and laser parameters. Users can experiment with combining additive and metal removal processes to determine optimal safe hybrid manufacturing methods.

"Additive manufacturing applications create new possibilities for manufacturers," Granata said. "Adding this technology to VERICUT provides unique solutions that bridge the gap between designing for AM and choosing the best manufacturing strategies for their parts."

New Module: Teamcenter Interface

VERICUT Tool Manager imports 3-D cutting tools from Siemens Teamcenter Product Lifecycle Management (PLM) software. VERICUT connects directly to Teamcenter to reference files, avoiding the need to create external uncontrolled copies of models on a local or network drive. In the NX CAM project, all cutting tools used in a given project are listed. In one step, all 3-D cutting tools for a job are imported at once.

New Module: Grinder-Dressing

VERICUT enhances support for grinding and dressing operations. Users can simulate dressing where a secondary tool is applied to a grinding wheel to freshen the grinding surface, or to change the grinding wheel cutting shape. VERICUT simulates the dynamic compensation needed while the dresser is used, even while the grinder is engaged with the part.

Force Optimization

VERICUT's Force module is a physics-based NC program optimization method that maximizes chip thickness. Force creates more constant cutting forces resulting in significant machining time savings. Graphs and charts are displayed in real-time, revealing cutting conditions and forces as they are encountered by cutting tools. The data helps NC programmers identify undesirable cutting conditions represented as spikes in the graphs. Spikes display forces, chip loads, tool deflection and material removal rates above the recommended parameters. With one click on the chart, the exact location in the NC program is marked. Simultaneously, the actual cut in the graphics window is displayed. By optimizing toolpath feedrates, Force reduces machining time, prolongs tool life and produces a higher quality finished product.

Enhanced Sectioning

VERICUT's new Section window is easier and faster to see inside a part during simulation. This allows the user to check proper fit and identify interference between the workpiece and machine components. Sectioning abilities in machine view help with complicated machines where visibility is challenged. Enhancements allow the simulation to be continued while sectioned and zoomed to achieve unobstructed viewing to pinpoint highlighted errors.

X-Caliper Dimensions

The X-Caliper measuring tool creates a measurement label on the part, and label placement is customizable for optimal viewing. Multiple dimensions can be displayed on the part to quickly document key measurements, create set-up diagrams or inspection aids. Images with dimensions are easily referenced in VERICUT reports.

Improved Report Template

VERICUT's Report Template editor makes creating a custom report easier. Adding content directly to the report editor is simplified using standard word processing capabilities. The enhancements allow the use of standard HTML objects, and the template editor displays what the report will look like as the template is designed, which also shortens the design process.

For more information contact:

CGTech

9000 Research Drive

Irvine, CA 92618

949-753-1050

info@cgtech.com

www.cgtech.com