The TT150 tilting table features large diameter worm gears to minimize wear even at high torque levels.

The CK160 is super-compact, with a thin body and a small footprint.

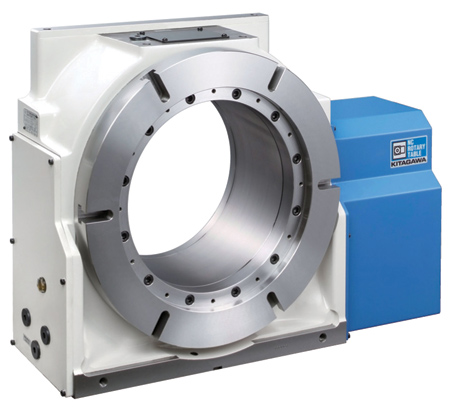

TP 530 has a large through-hole and is designed for petrochemical applications.

Kitagawa rotary tables from Tecnara Tooling Systems offer high production capacity and accuracy. All models are engineered for compactness, versatility and robust operation under the most demanding conditions.

Economical, high-performance MR series tables feature accuracy within 20 seconds in most models, a powerful triple disc air clamping system and high-speed table rotation up to 50 RPM for the model MR120.

TX Series tables feature a built-in air booster for maximum clamping force. Inductosyn and rotary scale options are available for most models. Motor covers are air-purged to keep out moisture and foreign materials. To facilitate a simple and clean air/hydraulic piping arrangement, a built-in rotary joint option is also available.

The TP Series tables are intended for large workpieces common to petrochemical applications. The TP530 is a large, ultra-light and compact table with a 13.6" diameter through-hole. The newly introduced TP430 is a smaller version with a 10.8" diameter through-hole. A wide variety of scroll chucks are available for both models.

"The super-compact CK series features the world's thinnest bodies and smallest footprints," said a company spokesperson. The CK160 is 3.9" deep, nearly 2" thinner than a conventional rotary table. This provides a wide machining area that is suitable for use with a trunnion fixture. CK Series tables are available with or without a block-less rotary joint.

Kitagawa TT and TW series tilting rotary tables employ a dual axis design that permits any compound angle and eliminates additional set-up. The compact stationary tilting motor case minimizes interference problems. Most models feature a built-in air booster for maximum clamping force.

All Kitagawa rotary tables feature large diameter worm gears to increase engagement area, thus decreasing pressure on contact areas. This minimizes wear even at high torque levels. Wear is further reduced by a new worm gear material with a high silicone aluminum content and an extra-large cross roller bearing that eliminates radial and thrust play, thus preventing displacement under heavy loads.

For more information contact:

Tecnara Tooling Systems

12535 McCann Dr.

Santa Fe Springs, CA 90670

562-941-2000, fax 562-946-0506

la@tecnaratools.com

www.tecnaratools.com