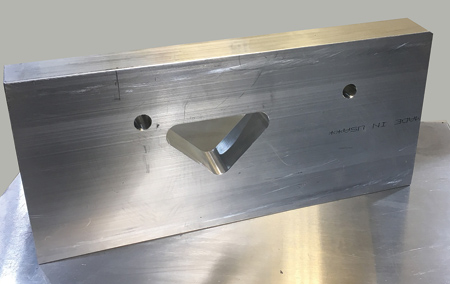

Wayne Automation's Aluminum Case Erector part before machining.

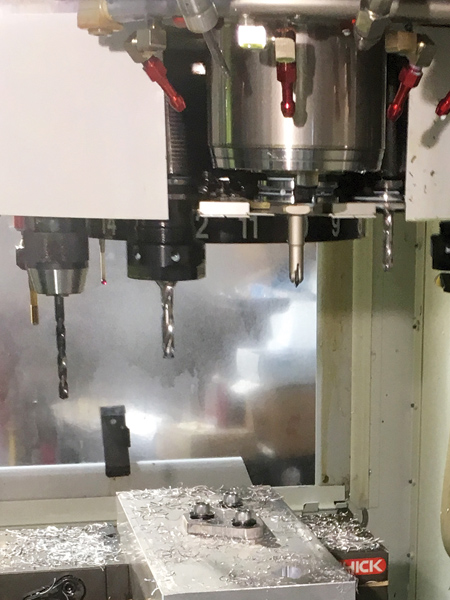

Dave Carlberg Jr., CAM Programmer, operates a Haas VF-2.

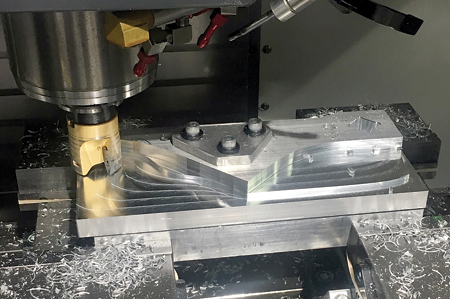

Dave Carlberg Jr., CAM Programmer, sets up the Haas VF-2 to machine a pick arm block for Wayne Automation's VCE Case Erector.

Tool changeover and drilling operation

Roughing profile work in process

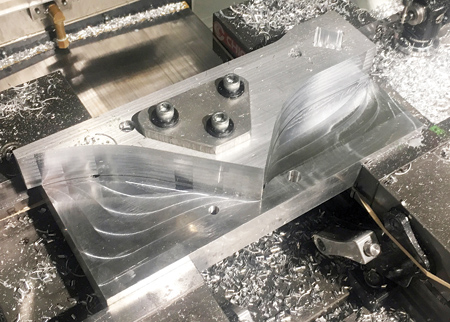

Finished pick arm block in the VF-2

Completed pick arm block machined on the VF-2 with additional detailing done in another machine set-up.

Dave Carlberg Sr., Foreman, and Dave Carlberg Jr., CAM Programmer, with the Haas VF-2 and completed part.

Sommers (sidebar): Phillips OPTO expert Joe Sommers works with manufacturers to troubleshoot processes and identify new ways to increase productivity and profits.

Wayne Automation knew something had to change. For almost a decade, the packaging equipment maker had been outsourcing 80% of its machine shop work. But as the company grew, the strategy no longer fit.

"Our suppliers could not keep up with our growth, and our designers were innovating faster than vendors could respond," said Jay Bachman III, Vice President and General Manager of Wayne Automation. "We had armies of assemblers constrained by a lack of parts."

Just-in-time manufacturing-not to mention mid-stream design improvements-was virtually impossible.

To regain control, Bachman made the bold decision to bring parts production back in-house for the first time in a decade. But after purchasing a new CNC, he realized he needed more than a "hot new machine." "The machine was only producing at a tenth of its capacity; I knew something else was going on," he said.

While the machine was state-of-the-art, the production processes and skills needed to support it were outdated. Bachman knew it was time to create a shop in line with the rest of the company's cutting-edge product designs, assembly and customer service.

Partnering with Phillips Leads to Results

To rebuild its machine shop, Bachman turned to Phillips OPTO for help. OPTO for Haas is an innovative Phillips program that provides companies with high level manufacturing expertise to help them achieve rapid productivity and quality gains.

Over several months, OPTO experts partnered with Wayne Automation to:

- Revamp its machine shop based on industry best practices

- Troubleshoot production for hidden productivity gains

- Provide hands-on training in set-up, tooling, offline programming and quality control.

Today, production levels are at their highest in 40 years with CNC machines operating 10 times more efficiently. Wayne's job book is overflowing, and the company's parts shop has become a model for other local manufacturers. "Companies are coming to see us now," Bachman said.

As for Bachman's goal of taking parts production in-house? It succeeded-Wayne now produces 95% of its own parts.

Bachman credits Phillips OPTO with helping to jump-start the company's transformation. "They opened our eyes, and showed us exactly what we needed to do to get our shop up and running," he said. "It was one of the easiest, highest payback investments we have ever made."

The Road to Success

Bachman remembers the first day Joe Sommers-one of Phillips' top OPTO manufacturing experts-came to the plant.

"He took a slab of aluminum, modeled a part on his laptop and ran the machine at maximum capacity," Bachman said.

People started coming from all over the factory-gathering at the windows and leaning in to get a better view. "No one had ever seen a high-speed cutter flying through metal like that," Bachman said. "The light bulb went off."

Sommers went on to make recommendations about tooling, set-up, programming and quality control. He was especially focused on productivity and spent time observing employees to find more efficiency gains.

He noticed the company was using a highly skilled toolmaker who programmed by hand at the control. To increase machine productivity, Sommers trained several employees to program offline using sophisticated CAM software. He also showed the team how to operate an electronic probe to ensure correct set-up-critical to efficiency and quality control.

"Our people caught on fast. Parts started coming out quickly and to a standard we had not seen with our vendors," Bachman said.

Before long, Wayne Automation had five new Haas CNC machines, all operating at full capacity. Cost savings, not to mention dramatic reductions in lead times, quickly followed.

Overall, OPTO for Haas helped Wayne Automation:

- Increase CNC production tenfold

- Move 95% of parts production in-house

- Lower production cost by 20%.

"It was an easy spend in hindsight. We have earned our investment back many times over," Bachman said.

Teach a Man to Fish

"A lot of manufacturers think spending begins and ends with a new machine purchase," Bachman said. "Investing in expertise, however, needs to be part of the equation, especially given the complexity of technology and the need to constantly upgrade manufacturing processes."

"When you work with Phillips, you can access the latest in production trends from across the entire manufacturing industry," he added.

These days, Wayne Automation calls Sommers now and again to ask a question, but the company is largely self-sufficient.

When describing the skill set Phillips left behind, Bachman referred to the old proverb: "Give a man a fish and feed him for a day; teach him to fish and feed him for a lifetime."

"OPTO taught us how to fish," Bachman said.

Wayne Automation is a provider of high-speed, high-reliability packaging equipment. The company builds customized packaging systems that reduce material loss and increase production uptimes. Its packaging equipment can be found in plants around the world, from glass container factories in Canada to beverage producers in Central America and the United States.

What is OPTO?

Machining is all about gaining that extra edge, but how can companies keep up when they are already juggling so much?

"It is a lot for any single manufacturing company to tackle alone," said Alan Phillips, President of Phillips Corporation, a global supplier of manufacturing technology products and services.

That is why Phillips Corporation created OPTO for Haas-an innovative service that provides state-of-the-art machining expertise, process engineering support and highly targeted on-site skill development to help companies achieve rapid productivity and quality gains.

"Companies are asking, `where is machining going?' `Are our processes as efficient as they could be?' `Do our people have the skills to run with new technologies?'" Phillips said.

With so much riding on the answers, there is a need for tools like OPTO, he said.

The program is designed for manufacturers using Haas machinery and is taking off rapidly as companies seek low-cost ways to increase productivity. Recently, OPTO for Haas experts have partnered with manufacturers to:

- Design new processes

- Optimize programming, set-up and tooling

- Prove out new parts

- Troubleshoot overall production for hidden productivity gains

- Revamp machining processes to reduce cycle times

- Fast-track employee skills.

"One of the biggest benefits for customers is the access to best practices," Phillips said. "OPTO experts-made up of former shop managers, CNC programmers and process engineers-have worked with hundreds of companies, giving them unparalleled access to best practice. These are people who have been in a lot of shops. They have seen a lot, they have solved some very tough problems and they can share that with our customers."

Sharing knowledge is "hardwired" into the program, Phillips said. "Some experts want their customers to know as little as possible. We are the opposite. We want to do as much competency transfer as we can."

For more information contact:

Wayne Automation Corporation

605 General Washington Avenue

Norristown, PA 19403

610-630-8900

www.wayneautomation.com

OPTO for HAAS

215-245-4185

opto@phillipscorp.com

www.phillipscorp.com