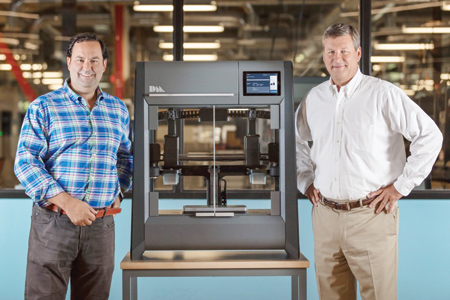

Morris Group, Inc. has been selected by Desktop Metal as a Diamond Partner supplier of its innovative metal 3-D printing systems. (l-r) Ric Fulop, CEO and co-founder of Desktop Metal and Brad Morris, President and CEO of Morris Group, Inc.

Morris Group, Inc. of Windsor, CT, one of the largest CNC machine tool distribution networks in North America, has been selected by Desktop Metal of Burlington, MA, as a Diamond Partner supplier of its innovative metal 3-D printing systems in 30 states extending from Maine to Florida to the Dakotas. With the addition of Desktop Metal's Studio System to its existing lineup of CNC machine tools, Morris Group's extensive distributor network provides an end-to-end suite of advanced solutions to manufacturers of precision metal parts.

"We are very pleased to represent Desktop Metal and excited to introduce this groundbreaking 3-D printing technology to metalcutting manufacturers in our distribution area," said Brad Morris, President and CEO of Morris Group. "Our organization brings more than 75 years of manufacturing experience, knowledge and customer support to the table."

The Studio System, which debuted in May, is the first office-friendly metal 3-D printing system for rapid prototyping, and is 10 times less expensive than existing technology. It is a complete platform, including a printer, a debinder and a sintering furnace. It requires no hazardous powders, lasers or cutting tools to operate. Instead it uses Bound Metal Deposition (BMD), a proprietary process, to near net shape parts, similar to the safest and most widely-used 3-D printing process for plastics, fused deposition modeling (FDM). The Studio System printer features safe-to-handle, swappable media cartridges and quick release print heads for seamless material changes. It was designed for use with a variety of materials - from steels and copper to superalloys like Inconel.

"We are excited to partner with Morris Group to bring our metal 3-D printing solutions to new markets," said Ric Fulop, CEO and co-founder of Desktop Metal. "Through this partnership, manufacturers can leverage the same trusted source to purchase and service the highly complementary technologies of CNC machine tools and metal additive manufacturing that together deliver the dimensional accuracy and speed needed to produce reliable, precision metal parts."

"We researched many different additive manufacturing technologies over the past several years and believe that Desktop Metal offers the best metal 3-D printing tool for our customers' needs. We look forward to introducing the Studio System and other Desktop Metal products to the market as they are developed," added Mr. Morris.

For more information contact:

For more information or to reserve the Studio System, contact your local Morris Group distributor. To locate a Morris Group distributor near you, visit www.morrisgroupinc.com/home/companies.

Morris Group, Inc.

910 Day Hill Rd.

Windsor, CT 06095

860-687-3475

www.morrisgroupinc.com

Desktop Metal

www.desktopmetal.com