The new PROMOS 3+ monitoring system from PROMETEC provides even more process safety for machining.

PROMETEC, a manufacturer of monitoring solutions for machining processes and part of Sandvik Coromant, offers its PROMOS 3+ system. "This advanced connectivity solution, which provides a first look at Big Data and the industrial internet of things (IIoT), is considered an important component for the Industry 4.0 initiative from Sandvik Coromant," said a company spokesperson.

PROMOS 3+, a refinement of the proven and tested PROMOS 2 system, offers even more process safety for machining processes. As a monitoring system, it is designed to ensure that the right tool is in place and that the process is completed within defined parameters.

"PROMOS 3+ stops the machine if the tool is missing, breaks or collides with the workpiece," said Dr. Klaus Kristoffel, Managing Director of Prometec. "If the work process veers from predefined parameters, this is corrected by the system. In addition, PROMOS 3+ is tailored to user needs and provides warning of impending tool wear or breakage."

The PROMOS 3+ monitoring system is in continuous communication with the machine. It gets its signals either directly from the machine's digital drive data or from sensors that monitor parameters such as force, structure-borne noise or active power against limit values. "The system's advantages include improved process safety, longer tool life and assured component quality. Furthermore, less tool breakage is likely to occur, along with less damage in the event of a collision. As a result of these benefits, machine shops will also find that downtime is minimized, while the potential for unmanned machining increases," said the spokesperson.

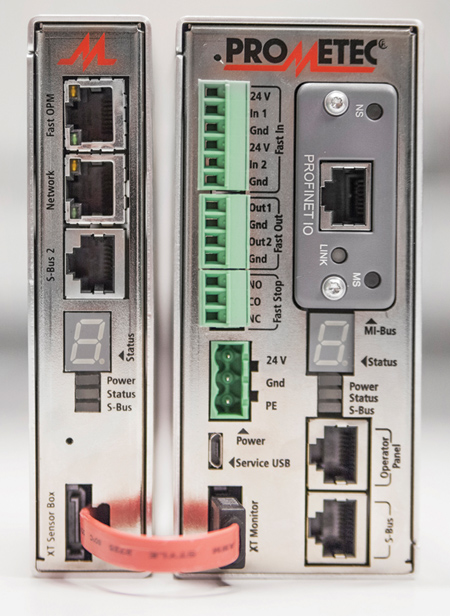

"Due to PROMETEC's Compact Monitor, intelligent vibration sensor and cost-effective control element, an economical collision detector has been created that can be scaled into a comprehensive multi-level, multi-channel monitoring solution," said the spokesperson. Further benefits of the modular PROMOS 3+ include complete independence of specific control types, compact hardware modules that require little space in switchgear cabinets (all connections and displays are on the front), quick and easy installation and set-up and little training required because of automated functions for adaptation to customer systems.

For more information contact:

Prometec Inc.

47711 Clipper St., Suite 200

Plymouth, MI 48170

734-455-0100

www.prometec.com

Sandvik Coromant

1702 Nevins Road

P.O. Box 428

Fair Lawn, NJ 07410-0428

800-SANDVIK / 201-794-5000

us.coromant@sandvik.com

www.sandvik.coromant.com/en-us/campaigns/pages/coroplus.aspx