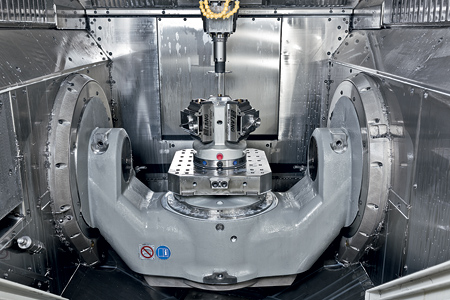

The working area of a C 22 U high-performance 5-axis machining center featuring a 320 mm diameter NC swiveling rotary table with a multi-clamp system

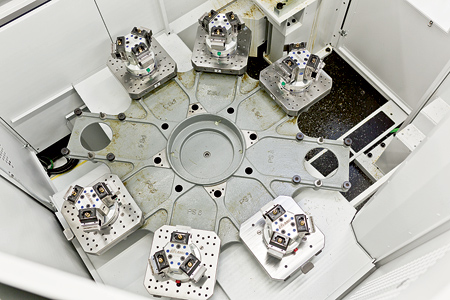

The 8-pocket pallet magazine for the PW 250 pallet changer, together with a pallet changer and pallet holding fixture on the table of the C 22 U high-performance 5-axis machining center. The system comprises a total of 11 pallets.

(l-r) Sascha Riesinger, Sales Manager; Dipl.-Betriebswirt (FH) Jürgen Stickel, Managing Director; and Bernd Zepf, Production Manager, Fetzer Medical

"From idea to finished product" is the mission statement of Fetzer Medical GmbH & C. KG, a medium-sized company based in Tuttlingen, Germany, that develops and manufactures surgical instruments and medical devices.

In 2008, in order to further build this family business, Peter Fetzer set out to establish the company as an independent OEM. Fetzer Medical launched an extensive capital investment, qualification and certification program. The process began with the purchase of 5-axis machining technology to provide a fast and flexible approach to varying product and batch sizes.

Today, Fetzer Medical supplies its customers with ready-to-use products, from prototypes/individual parts to large production runs and complete systems. The business currently employs 45 highly qualified employees and state-of-the-art equipment. Roughly 75% of the work, which involves complex milling/drilling operations in titanium and other relevant materials, is done on high-performance Hermle 5-axis machining centers.

From Manual Single Part Fabrication to Industrial Production

Fetzer Medical Production Manager Bernd Zepf commented on the choice of Hermle machines: "The Hermle machines feature a robust gantry design, and the machine concept of 3 axes in the tool and 2 axes in the workpiece results in optimum tool accuracy. Excellent accessibility is another key factor. These features make them ideal for 5-axis complete machining in one or two set-ups. Further, our employees, including myself, had already had very good experience in the past with Hermle machines: their control and programming, their comparatively simple operator control, including responsive and highly competent service backup. That experience helped us to immediately get started with 5-axis technology, which we launched in 2008 by acquiring a Hermle C 40 U high-performance 5-axis CNC machining center."

As the business flourished, capacity had to be increased, and a number of Hermle machining centers - some of them highly automated - were added. Fetzer Medical today runs five machining centers, assuring the prompt execution of its OEM production orders. While the first purchased 5-axis C 40 U machining center was initially used to cement the business' manufacturing expertise, the machine is now primarily used for pre-fabrication and for machining prototypes, samples and short runs. Two C 22 U high-performance 5-axis machining centers are equipped with 11 pallet changers/magazines type PW 150, and are used for the automated flexible production of a wide range of components in runs of up to 300 pieces.

Validated and Certified Production Processes

A further automation level includes a C 12 U high-performance 5-axis machining center combined with an RS 05 robot cell for the production of modular designed scissors. A C 800 V CNC machining center was added to the range of Hermle machines to provide flexible and universal operation in pre-production, including making reference surfaces and jigs and fixtures.

Since all of the installed Hermle machining centers are essentially based on the same concept and on the same control and operating philosophy, operators are quickly familiarized with running the various machines, and staff confidence and acceptance of the machinery is enhanced as a result. This is advantageous in terms of the productivity of the machines, which are run basically in single-shift mode under operator control, although the machining centers with the pallets and robot system do run overnight and on weekends for automated machine loading.

"These `hard facts' are complemented by a number of `soft facts' that are essential for the highly complex machining of surgical instruments and medical technology devices," said a company spokesperson. "Since - according to EU and U.S. institution specifications - production and quality assurance equipment needs to be fully validated and certified in the surgical and medical technology sector, it is a major advantage in terms of U.S. certification that many U.S. medical technology firms use already validated Hermle machining centers for their production lines." This also ensures simpler and faster validation cycles for Fetzer Medical, thus resulting in a faster time-to-market for its customers.

For more information contact:

Fetzer Medical GmbH & Co. KG

www.fetzermed.com

Hermle Machine Company, LLC

5100 West Franklin Drive

Franklin, WI 53132

414-421-9770

info@hermlemachine.com

www.hermlemachine.com