In-Process Correction Technology for Hybrid Metal 3-D Printer

September 1, 2017

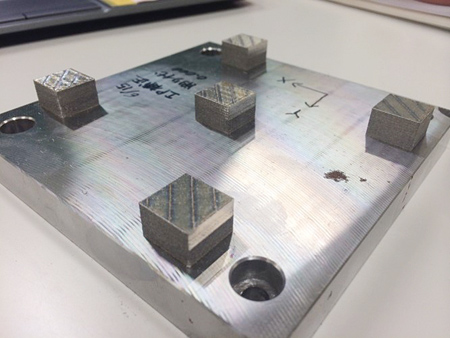

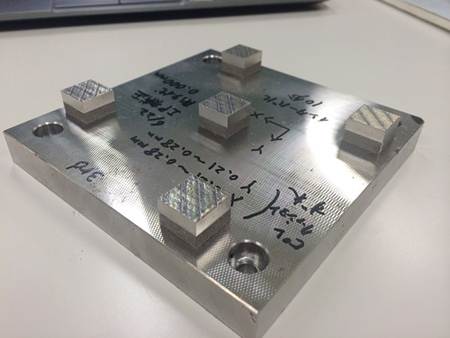

(left) without alignment (right) with in-process correction technology

Machine tool manufacturer, Sodick, has announced the development of a new In-Process Correction System for its additive manufacturing platform, the OPM Metal 3-D Printer. Using a CCD camera installed within the machine, Sodick's In-Process system aligns the OPM's 500W fiber laser and 45,000 RPM spindle, and automatically corrects its positions and performs realignments when they become due in the maintenance cycle. Through use of this interior CCD camera, the precision of both the laser sintering and the milling process are increased.

In addition to reducing the frequency of maintenance required by the OPM, this correction system enables greater process accuracy. The improved accuracy of the machine further makes it possible to program a smaller offset, ultimately reducing the amount of machining time required by up to 25%. "Sodick's In-Process system thus makes it possible for customers to produce parts faster and more reliably, with less frequent maintenance," said a Sodick spokesperson.

For more information contact:

Sodick Inc.

1605 N. Penny Lane

Schaumburg, IL 60173

847-310-9000 / 888-639-2325

info@sodick.com

www.sodick.com

< back