The Amada Regius 3015 inside of AST Manufacturing's shop.

Parts picking robot taking completed parts out of their nests and placing them on designated pallets.

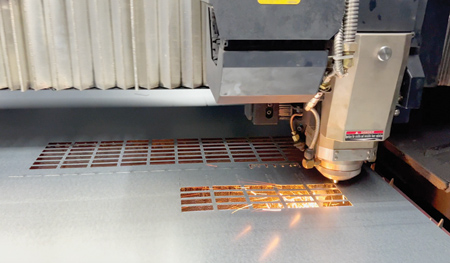

Flash cutting inside the Regius fiber laser.

AST Manufacturing in Grand Prairie, TX, has announced the addition of an Amada Regius 3015 AJ Laser, which is Amada's fastest laser. The installation at AST marks the second Regius 3015 in the United States, the company reported.

This machine is accompanied by the AMS 3015 CL Automated Material Feeding Tower and TL3015L Parts Picking Robot. The feeding tower and parts picking robot allow for automated loading and unloading of sheets to and from the laser while laser cutting at the highest rates of speed on all types of materials. Having the ability to automate loading, unloading and picking parts improves output and provides faster turnaround times, all while allowing for 24-hour operations. "The addition of the Regius laser creates endless opportunities for parts and products to be created. From thin to thick materials, all shapes and sizes," said a spokesperson.

Owner Tony Woodall said: "This Regius laser will allow us to cut a wide range of material at the quickest speeds without sacrificing quality. We now have the opportunity to run around the clock in a lights-out manner due to the automation of the loader and robotic parts picker. This will help shrink our lead time and improve our ability to satisfy our customers."

"Laser cutting is prevalent within the manufacturing industry, but AST wants to stand out by keeping up with the new and improving technology," said the spokesperson. "AST's strategy has always been that of niche supplier, creating products that other shops cannot. Amada has been a great partner as the new Regius is AST Manufacturing's third laser they have purchased and sixth Amada machine overall."

Another aspect new about the business is the updated name. Since 1993, AST Waterjet was a pioneer of the waterjet cutting industry in Dallas/Fort Worth. However, after adding to its capabilities and seeing significant growth a name change was required. Thus, the birth of AST Manufacturing. AST's mission is to provide the highest level of customer service, satisfaction and quality while utilizing the latest advances in CNC manufacturing technologies in laser cutting, router cutting, CNC machining, waterjet cutting, press brakes and other metal fabricating/assembly technologies. AST's Quality Manual is third party certified to meet the ISO 9001:2015 quality standard.

For more information contact:

AST Manufacturing

1000 Avenue N

Grand Prairie, TX 75050

972-554-0383

ast@astmfg.com

www.astmfg.com