CNC Chamfering Solutions

February 1, 2022

ChamferCut-CG (collision gear)

ChamferCut-IG (internal gear)

FlexChamfer

v

Chamfering gears prevents the edges of the teeth from becoming brittle during heat treatment and reduces transportation and installation damage. Multiple processes can be chosen for this. Classic technology, such as press deburring or chamfering with end mills, is increasingly being superseded by CNC controlled processes such as ChamferCut and FlexChamfer. These are economical and offer high chamfer quality that can be reproduced very precisely. CNC controlled processes are easy to operate and minimize set-up cost.

"Liebherr knows the advantages and the limits for the various processes and individually advises customers with their selection," said a company spokesperson. Requirements for an optimal chamfering process can be individually arranged by batch size, chamfer shape, subsequent machining or component geometry. Liebherr specializes in particular in the ChamferCut technology from LMT-Fette.

ChamferCut

Features and benefits of ChamferCut:

- Precise chamfering geometry and quality, no material deformation

- Can be reproduced very precisely

- Easy operation, short set-up times due to CNC control system

- Single-cut strategy: No additional finishing cut required to remove bulging on the lead

- Low investment cost and long tool life

- Ideal for subsequent finish machining

- Integrated chamfering device or standalone machines from Liebherr enable parallel machining

- Application range module 0.5 mm to 36 mm.

ChamferCut CG (Collision Gear)-Chamfering Despite Interfering Contour

Features of ChamferCut CG:

- Deburring the tooth space to the tooth root surface, even on interfering contours. Chamfering including the root, even for collision critical operations.

- More degrees of freedom with the chamfer divided between the left and right profile

- Can be implemented on Liebherr machines with a simple software update

- Batch sizes: Suitable for medium and large-scale production

- Application examples: Truck shafts, passenger vehicle idle gears and ring gears, industrial gearboxes.

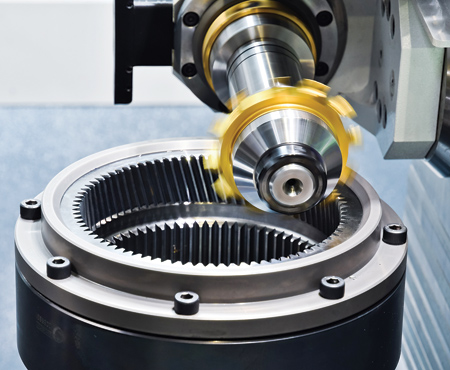

ChamferCut IG (Internal Gear)-Chamfering of Internal Gears

Features of ChamferCut IG:

- Chamfering of internal gears on both flanks in one cut

- Machining on compact standalone machine, e.g., LD 180 C

- Application examples: Internal gears of planetary and eMotive gearboxes.

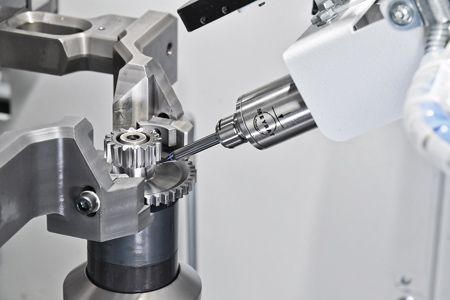

FlexChamfer-Maximum Flexibility for External and Internal Gears

Features of FlexChamfer:

- CNC controlled advanced development of chamfering with end mills

- Development of variable chamfering forms with standard catalog tools

- Particularly suitable for external gears with or without interfering contours, as well as shafts and internal gears

- Use in hobbing, shaping and gear skiving machines

- Parallel to machining (depending on the main machining time)

- Ideal for small and medium batch sizes

- Examples of use: Stage planetary gears, double internal gears.

For more information contact:

Liebherr Gear Technology, Inc.

1465 Woodland Drive

Saline, MI 48176-1259

734-429-7225

info.lgt@liebherr.com

www.liebherr.com

< back