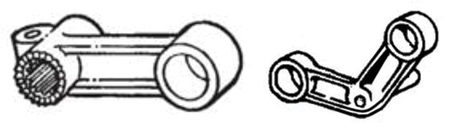

Hand-drawn technical illustrations of a cross shaft arm and bellcrank, dating from the 1960s. These obsolete cold start parts were originally conventionally manufactured.

Bellcrank and cross shaft arm, metal 3D printed in colbalt-chrome on a GE Additive M2 Series 5 machine.

Building on the earlier success and momentum of the Pacer Edge program, the U.S. Air Force (USAF) and GE have entered Phase III of its metal additive manufacturing (AM) pathfinder. This phase tackles the USAF's sustainment behemoth of "cold starts" head-on.

Aircraft engine components that are considered cold starts are parts that take over 300 days to procure. It is estimated that the USAF has over 800 engine cold starts each year.

"The first priority for the USAF and GE team has been to create digital 3D technical data packages (TDPs) for hard to procure, obsolete cold start parts and deliver four airworthy, near-net castings. These TDPs will eventually mean that part obsolescence will be a thing of the past," said Alexa Polites, USAF Pacer Edge Program Manager, GE Additive.

Over the coming years, the joint USAF and GE team plans to create at least five TDPs, increasing in technical complexity, across the USAF's sustainment platforms.

"The teaming of GE and the USAF legitimizes utilization of AM to address critical needs of the aging aircraft that are currently unsupported within the existing supply chain," said Zack Miller, Chief, Advanced Manufacturing Program Office, Air Force Rapid Sustainment Office.

"Pacer Edge is accelerating the USAF's widespread adoption of 3D metal printing to organically solve supply chain shortages and realize its promise to improve warfighter support by drastically reducing lead times and creating additional sourcing options," said Beth Dittmer, Chief, Propulsion Integration Division, Tinker Air Force Base (AFB).

Phase III has already successfully printed two components, a bellcrank and a cross shaft arm, in cobalt-chrome on a Concept Laser M2 Series 5, located at GE Additive's facility in Cincinnati, OH. Work has also progressed on additional components using Alloy 718.

The cornerstone of the USAF/GE Pacer Edge program is the creation of organic capabilities at Tinker AFB. One way to achieve that is by ensuring that intellectual property generated within the Pacer Edge program is owned by the U.S. Government. This will enable the USAF and Department of Defense to print these parts themselves in the future. The program remains on schedule with the goal to have airworthy production castings delivered to the USAF in Spring 2022.

"In parallel to the TDP creation, GE Additive is working closely with our USAF peers to transfer the production capability to the Tinker AFB Depot. This will establish an organic, airworthy, metal 3D printing capability for the USAF," said Joe Franzen Jr, Technical Account Manager, GE Additive.

For more information contact:

GE Additive

www.ge.com