The Tornos SwissNano is available in many colors.

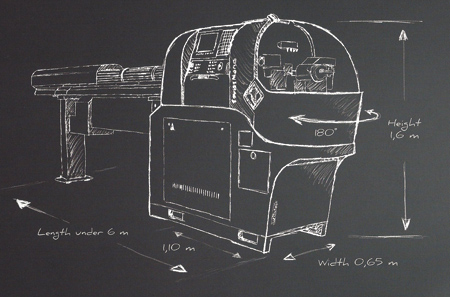

The SwissNano, engineered by Tornos to machine small components, takes up less space than the Tornos M7 cam machine. Three SwissNano machines can fit into a width of 3.2 meters wide. The kinematics of the machine are designed to produce small, high precision parts. The symmetrical cast iron base gives the machine rigidity, which produces excellent surface finishes.

The SwissNano is capable of gear hobbing and deburring, rough finishing, turning and drilling. The machine comes standard with a fixed guide bushing and oil filter, front platten rotating tool motor, C1 axis, polygon operation and gear hobbing function programming, thread milling device, gear hobbing device, radial drills, adjustment of S4 counter spindle end of clamping, pneumatic ejection of workpiece plus air/oil cleaning of collet and automatic centralized lubrication cycle.

Productivity can be enhanced by installing a vacuum to perform part pick-up during main and counter operations.

Specifications of the SwissNano:

- Bar capacity: 4 mm

- Workpiece length capacity: 28 mm

- Spindle rotation speed: 0-16,000 RPM

- Number of linear axes: 6

- Number of C axes: 2

- Number of tool positions on guide bush: 7

- Turning tool section: 8x8

- Number of tool positions: 12

- Positions for radial rotating tools (option): 2 positions

- Rotating tool speed: 8,000 RPM

- Counter spindle tool positions for rotating tools: 3.

Options available for the SwissNano include HF spindles, carousel collection system for parts, vacuum for picking up parts, fire extinguishing device and oil mist extractor. A connectivity package can facilitate communicating and programming the machine, as well as monitoring the machine and its tools.

The machine is available in several colors to enhance a shop floor. To see the machine in action, go to tornos.com/en/content/swissnano.

For more information contact:

Leonard Lanute

Tornos Technologies U.S. Corp.

840 Parkview Blvd.

Lombard, IL 60148

630-812-2040

lanute.l@tornos.com

www.tornos.com