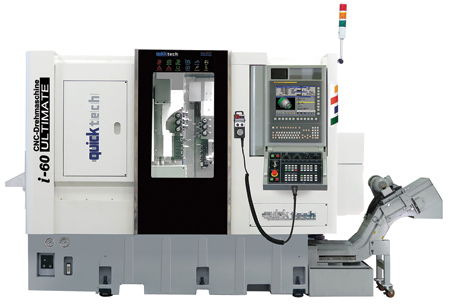

Quicktech i-60 Ultimate CNC turning center

Absolute Machine Tools has announced that it is the exclusive North American distributor of the Quicktech line of CNC turning centers. "We carried the line in the late 90s and are happy to have it once again as another quality choice for our customers," said Steve Ortner, President of Absolute Machine Tools. "The manufacturer has significantly improved the design and construction of the products; we are confident to stand behind this line once again."

The i-42 Ultimate and i-60 Ultimate high-production CNC turning centers from Quicktech permit complete machining, including complex milling operations, of medium-diameter bar stock. With two turning spindles, two milling spindles and two B-axes, these machines provide a total of 10 axes and capacity for up to 49 tools. Bar capacity for the 15 HP main spindle is 42 mm on the i-42 model (60 mm on the i-60), and 30 mm for the 7.5 HP sub-spindle on both models. Both main- and sub-spindles feature full continuous C-axes and are synchronized for fast, accurate part transfer.

The machines' tooling system provides part-making flexibility. A 4-axis (linear X,Y, Z and rotating B axes) gang-type vertical tool post serves each spindle. The main tool post has 6 O.D. turning tools, 5 I.D. turning tools and 12 live tools. The sub tool post features 5 O.D. turning tools, 9 I.D. turning tools and 12 live tools. Each tool post has a Y-axis for off-center milling operations. Live tools are mounted in a continuous 360° B-axis and powered by a 2 HP spindle motor. Rigid tapping is standard, as is the Kennametal KM-25 quick-change system that minimizes tool change time.

A matched Mitsubishi CNC system combines a Mitsubishi M830S control with a 15" (275 mm) LCD, Mitsubishi servomotors and amplifiers for reliability and performance. A Fanuc OiT-F, 15" (275 mm) LCD system, also with matched motors and drives, is available. Standard machine features include a bar feeder interface, parts conveyor and catcher, chip conveyor, collet chucks and a 400 PSI coolant pump.

The machine frames and all major components are cast from Meehanite iron. Large, 35 mm Hiwin roller type linear guideways and double-anchored, pre-tensioned 32 mm ballscrews maximize rigidity and precision.

"These compact, versatile machines enable manufacturers to produce precise, complex parts quickly, with the added benefits of the accuracy and consistency that result from processing the parts on a single machine tool," said Ortner. "These machines offer 2 X/Y/Z tool posts with a full B-axis at an extremely affordable price. Our customers will win big with this lathe."

For more information contact:

Courtney Ortner

Absolute Machine Tools, Inc.

7420 Industrial Parkway

Lorain, OH 44053

800-852-7825 / 440-960-6911

sales@absolutemachine.com

www.absolutemachine.com