Redesigned Oil Sight Glass Improves Contamination Monitoring

June 1, 2017

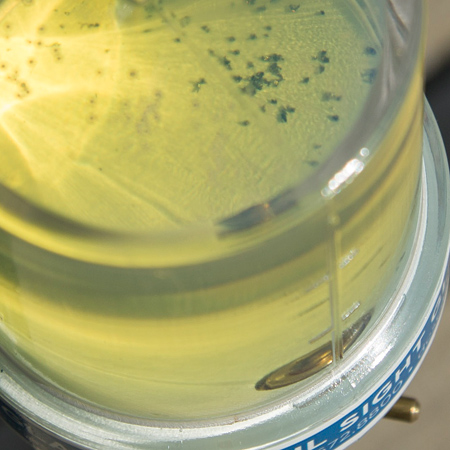

Vertical close up - contamination particulates easier seen against white background

Des-Case Corporation has launched a redesigned oil sight glass (OSG). A clear cylinder that installs in the drain port of the oil reservoir of pumps, gearboxes, bearing housings and other pieces of equipment, the OSG provides continuous fluid monitoring of the clarity, color, sediment and water contamination of the equipment's oil. An OSG plays a critical role in early detection of contamination and allows for constant monitoring of what is happening inside equipment that might degrade both oil and equipment life.

The most important improvement in the new Des-Case oil sight glass is the improved visibility in detecting machine wear and contamination. "Most OSGs have clear bottoms, making it more difficult to visually detect the presence of sediment in oil," said a company spokesperson. "Des-Case's new OSG has a white bottom that makes detection easier and more reliable. The redesigned device also has dual mount versatility for use in both horizontal and vertical applications, eliminating the need to buy two single-orientation OSGs. The sight glass' polyamide casing not only provides a crystal-clear view of the oil, but is strong enough to withstand the toughest environments."

Other improvements include a sloped floor for better sediment drainage, indication marks to easily monitor accumulation of water, and improved UV resistance and compatibility with all gear and mineral oils, most synthetic oils and diesel.

For more information contact:

Des-Case Corporation

675 N. Main St.

Goodlettsville, TN 37072

615-672-8800

www.descase.com

< back