"The Tool Manager in VERICUT 7.4 has been re-designed to enable easier user interaction," said a company spokesperson.

The VERICUT user interface is more customizable with new docking methods and a redesigned status window.

CGTech will demonstrate the new version of VERICUT CNC machine software at WESTEC in Los Angeles, CA, Sept. 15-17, Booth 1927. "VERICUT 7.4 includes many enhancements that further simplify the process of simulating a CNC machine," said a company spokesperson. "Changes to how users interact with VERICUT further improve VERICUT's workflow and simplify day-to-day NC programming and simulation use."

"This release increases the ability of manufacturing engineers to simulate the entire CNC machining process in order to produce better results and reduce the time spent in the programming and machining cycle," said CGTech Product Marketing Manager Bill Hasenjaeger. "VERICUT is constantly refined to provide the flexibility and tools our customers require."

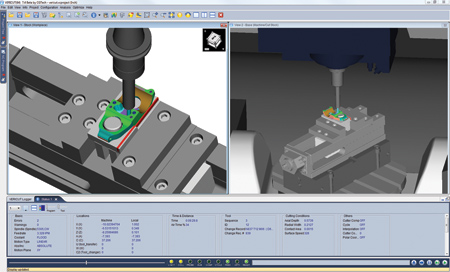

"VERICUT is CNC machine simulation, verification and optimization software that enables users to eliminate the process of manually proving out NC programs," said the spokesperson. "It reduces scrap loss and rework. The program also optimizes NC programs in order to save time and produce higher quality surface finish."

VERICUT simulates many types of CNC machine tools, including those from manufacturers such as DMG MORI, Mazak, Makino, Matsuura, Hermle, DIXI and Chiron. VERICUT runs stand-alone but can also be integrated with CAM systems such as CATIA by Dassault Systems, NX by Siemens PLM Software, Mastercam by CNC Software, PowerMill by Delcam, Edgecam by Vero and hyperMILL by Open Mind.

In version 7.4, a welcome screen automatically displays when first launching a VERICUT session. The welcome screen provides access to commonly used first actions for a VERICUT session.

"The VERICUT user interface continues to get more customizable," said the spokesperson. "VERICUT's desktop is enhanced with a new docking method enabling a user to lay out the VERICUT desktop in the most efficient manner for the way that he or she works. The new docking method is flexible and provides a high level of customization possibilities. Additionally, the status window is completely redesigned for better viewing, customization and size. The status window information is divided into information groups, each containing a specific list of information.

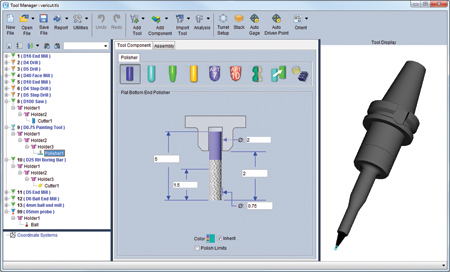

"Tool Manager's desktop and user interface is re-designed to enable easier user interaction. A new toolbar located at the top of the Tool Manager window consists of a combination of icons and pull-down menus providing access to all features needed to create and maintain tool libraries, create/modify tool assemblies, import tool assemblies and create or import OptiPath records. Also, in the tool list, tool components now have a Parent/Child hierarchy allowing for better tool assembly management and modification. All tool definition windows have been re-designed to make tool definition easier."

The spokesperson stated that other new features in version 7.4 include the following:

- New interfaces are available for integrating VERICUT with Creo Parametric 3.0, CAMWorks and SolidWorks.

- OptiPath now automatically works through multiple set-ups.

- Selecting a tool from the new Reviewer Tool Menu automatically sets the "Start" and "End" points of the simulation.

- Nearly 500 customer-driven enhancements and software change requests have been completed since version 7.3.

New Module

"Force is a physics- and mathematics-based modeling software designed to optimize machining rates for machined parts within aerospace, automotive, industrial and other markets that utilize automated machining," said the spokesperson. "Force determines the optimum speeds for a cutting process and makes the CNC machine cut in the most efficient, fast and reliable way, based on the type of material being cut.

"Force excels in difficult-to-machine materials, especially complex multi-axis cuts such as 5-axis flank milling. Once the material is characterized, it can be applied to a broad range of cutters and machines in future NC machining operations. It is easy to set up and can also predict tool wear."

For more information contact:

CGTech

9000 Research Dr.

Irvine, CA 92618-4214

949-753-1050

info@cgtech.com

www.cgtech.com

WESTEC 2015 Booth 1927