Laser marking workstation FOBA M2000 with advanced robotic machine. (Source: Flexxbotics)

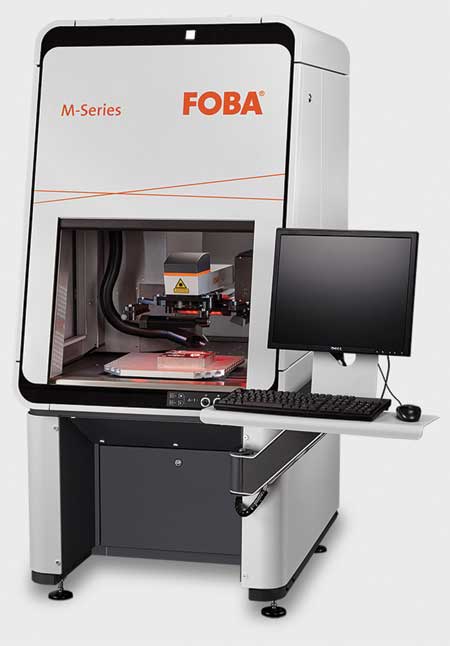

Laser marking workstation FOBA M2000. (Source: FOBA)

Laser marking and engraving is critical for unique part identification (UID), compliance and branding. However, capacity constraints and labor shortage issues can create serious throughput challenges.

"To increase output and improve profit per part, forward thinking manufacturers are transforming their laser marking operations with advanced robotic machine tending," said a FOBA spokesperson. "FOBA Laser Marking + Engraving works with Flexxbotics and Universal Robots to enable companies to achieve highest throughput and optimum marking quality."

Laser marking is a critical stage of the value stream for a product in many manufacturing processes. Bottlenecks can cause serious delivery problems and any mistakes can render the product unsellable. By introducing collaborative robotic automation with lean manufacturing principles, laser marking processes can be improved to enhance throughput and quality and reduce waste.

"Connecting robotic machine tending with our FOBA laser marking solution using Flexxbotics provides an even greater ROI," said Jeffrey A. Kniptash, FOBA's Sales Manager for Americas. "Enabling Flexxbotics robot-driven manufacturing with our FOBA laser marking and engraving equipment to enable autonomous process control can remove bottlenecks and deliver continuous operation."

Utilizing cobots from Universal Robots with Flexxbotics digitalization technology, companies running FOBA's laser marking and engraving machines can increase the machine-to-man ratio to 10:1 or more and run lights-out safely. Thus, they will benefit from additional capacity, high precision, optimum marking quality and improved profit margins. Flexxbotics includes communication with FOBA's integrated camera system for vision-based inspection providing closed-loop feedback to the robot for autonomous process control. FOBA's three-stage laser marking process HELP (Holistic Enhanced Laser Process), which includes part inspection prior to marking, automatic mark alignment and subsequent validation of the marking is coordinated with the robot actions. Flexxbotics utilizes either the Intelligent Mark Positioning (IMP) or Point & Shoot (P&S) capabilities in the FOBA equipment for precise alignment of the laser marker on the customer's product along with vision-assisted workflows for increased accuracy.

"Combining FOBA with Flexxbotics is particularly valuable in industries with strict regulatory compliance requirements that dictate the highest levels of repeatable precision, such as medical devices and surgical products along with aerospace, defense and space," explained Tyler Bouchard, co-founder and CEO of Flexxbotics. "Environments that require rapid and accurate processing like semiconductor and electronics operations also benefit substantially. With Flexxbotics and FOBA together customers can optimize cycle time, expand capacity and increase profit per part."

For more information contact:

FOBA Products Application and

Service Center

Videojet Technologies Inc.

1500 Mittel Blvd.

Wood Dale, IL 60191-1072

630-694-3243

fobasupport@fobalaser.com

sales-na@fobalaser.com

www.fobalaser.com

Flexxbotics

12 Channel St.

Boston, MA 02110

877-456-1576

www.flexxbotics.com

Universal Robots USA

27175 Haggerty Road, Ste. 160

Novi, MI 48377

844-462-6268

sales@universal-robots.com

www.universal-robots.com