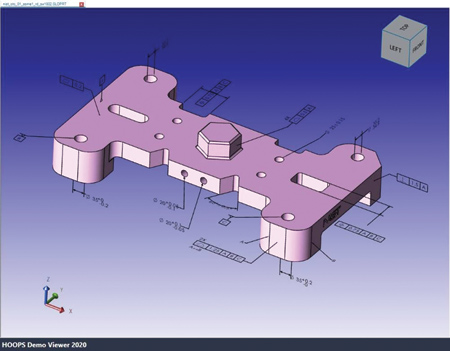

The HOOPS demo viewer allows engineers and developers to quickly test and review the HOOPS Exchange software development toolkit (SDK) for 3D web application development.

HOOPS Exchange 2020 improves support for manufacturing as a service (MaaS) applications.

Tech Soft 3D, a provider of software development toolkits to engineering software companies, offers HOOPS Exchange 2020, a fast and accurate CAD data access and reuse technology for manufacturing and architecture, engineering and construction (AEC) workflows.

"Digital transformation is happening at lightning speed within the manufacturing industry and we are committed to helping our partners, and potential partners, keep pace with this rapid momentum," said Lionel Vieilly, Product Manager at Tech Soft 3D. "Fast access to the full integrity of data, being able to use that data without the need for an additional translator, extreme performance with low memory usage-these are all paramount to quickly building robust, sophisticated 3D applications."

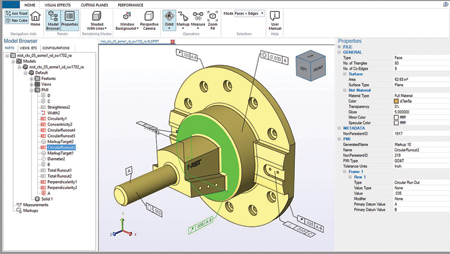

HOOPS Exchange 2020 continues to improve support for manufacturing as a service (MaaS) applications to help engineers improve and automate their processes, such as manufacturability analysis and costing, 3D printing and machining applications, and improve the quality of their semantic data.

These areas of enhanced support include:

- New format support for STEP-XML reader focused on CAD interoperability. Format updates include import of CATIA V5-6 R2019 (R29), Solid Edge 2020 and Siemens NX 1872.

- Feature tree now supports transformations like mirrors, translations and rotations.

- Feature support for SolidWorks assembly level holes.

- Improved feature tree support to access original extrusion and revolve sketches.

- Improvements in Semantic PMI for SolidWorks and PTC Creo.

- Support for names of physical materials for SolidWorks and Siemens NX.

- Improved geometric functions to provide BREP consistency in targeted applications.

- New progress bars to track progress of heavy process functions: Convert BREP to Nurbs, Model Sewing and Parasolid Bridge.

- Parasolid integration can now convert large tessellated models to the Siemens Parasolid kernel.

For more information contact:

Tech Soft 3D

1567 SW Chandler Ave, Suite 100

Bend, OR 97702

541-385-3000

www.techsoft3d.com/products/hoops/exchange