Bystronic showcased its new 30,000 sq. ft. Experience Center for the first time since moving into its new facility in February 2020.

For the first time, welding has been added to Bystronic Inc.'s portfolio with the Robotic Welding Cell, powered by CLOOS.

Press Brake Product Manager, Marcel Fiedler, demonstrating the Xpert Pro Modular Tool Changer.

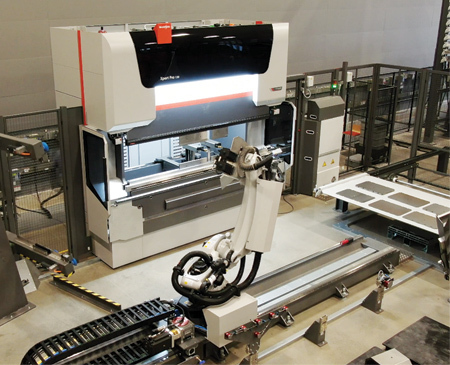

The Xpert Pro Bending Cell provides comprehensive automation from a single source.

Tube processing: The fully automated ByTube 130 3kW.

Bystronic Inc., the American subsidiary of Bystronic Laser AG in Switzerland, recently showcased its new Experience Center for the first time since moving into its new facility in February 2020. "The event was held over a course of 10 days and represented a solid effort to continue the annual Open House tradition while also adhering to local and state COVID-19 guidelines and restrictions," said a company spokesperson.

Smart Manufacturing Solutions for the American Market

The Competence Days event invited guests to view Bystronic's innovative product line that serves the laser cutting and bending manufacturing market. A total of six newly released products were demonstrated, including the ByStar Fiber now available with up to a 15 kW fiber laser source. "With its high cutting dynamics, thin to thick cutting capabilities and seamless automation solutions, the ByStar Fiber 15 kW laser cutting machine offers the best cost per cut part and shortest delivery times," said the spokesperson. Additionally, the ByTrans Cross automation component was demonstrated with the ByStar Fiber 15kW, highlighting a flexible solution for the loading and unloading of laser cutting systems.

Another addition to the laser cutting product line was the Next Generation BySmart Fiber, now available with up to a 10 kW fiber laser source. "The Next Generation BySmart Fiber opens up the full potential of fiber lasers to fabricators who want to gain a competitive edge with innovative technology and performance at an affordable price," said the spokesperson.

With the Modular Tool Changer option for the Xpert Pro, Bystronic takes the next evolutionary step in the field of bending with an intelligent sensor system and automated tool changing that saves time and increases bending quality in both thin and thick sheet metal. Flexible automation for fast and precise tool changing and reduced set-up time are offered by the Xpert Pro Modular Tool Changer.

With the Bending Cell for the Xpert Pro, Bystronic introduces a completely automated fixed bending cell. The cell features the Xpert Pro press brake and can be adapted up to the model Xpert Pro 320. The cell features a 7-axis robot for automated gripper changing, tool changing, press brake tending, loading of the bending blanks and unloading of the finished profiles. An automated re-gripping station enables the robot to re-grip the part during operations.

Bystronic has added to its tube cutting portfolio with the ByTube 130. The ByTube 130 3 kW achieves high cutting speeds in thin to medium material thicknesses. From tube bundle loading to automated tube loading, cutting and unloading, the ByTube 130 automates the entire tube cutting process. The ByTube 130 with up to a 3 kW fiber laser source, and tube diameter capacities up to 5" and lengths up to 28', also features low operating costs and low maintenance requirements, said the company.

A Strategic Partnership with CLOOS

At Competence Days, Bystronic Inc. introduced the first Bystronic Robotic Welding Cell powered by CLOOS to the U.S. market. CLOOS, with headquarters in Haiger, Germany, and offices in Schaumburg, IL, will supply the Bystronic Robotic Welding cells and provide installation, training and service, while Bystronic will be responsible for the sales and distribution of these machines.

CLOOS manufactures the robot weld positioner, the robot controller, the welding power source and the cell integration. CLOOS also maintains its own offline programming software, RoboPlan QRP Professional, for fast and easy programming.

Bystronic will offer three specific robotic welding cell models powered by CLOOS-Micro Cell, Compact Cell and Compact System-each having a specific scope of application based on the size and weight of the parts to be welded, and each with a two-station workpiece positioner.

The Micro Cell features an overall clamping length of 55" and a nominal load capacity of 280 lbs. per side for the manual rotating workpiece positioner, and a 400A welding power supply. The Compact Cell features an overall clamping length of 61" and a nominal load capacity of 562 lbs. per side for the automatic rotating work piece positioner, and a 450A welding power supply. The Compact System features an overall clamping length of 138" and a nominal load capacity of 2,248 lbs. per side for the automatic rotating workpiece positioner, and a 450A welding power supply. All welding cell models maintain an integrated safety system including nozzle search and anti-collision sensors, interlocked doors, safety enclosures with operator window, and when required, safety fencing and light curtain barriers. The Compact Cell and Compact System models include automatic Thru-Arc Seam Tracking for maintaining weld seam centering and integrity. The integrated forklift pockets for the Micro Cell and Compact Cell enable a quick installation and fast "ready to weld" integration into a customer's production environment.

For more information contact:

Bystronic Inc.

2200 West Central Road

Hoffman Estates, IL 60192

847-214-0300 / 800-247-3332

sales.us@bystronic.com

www.bystronicusa.com

CLOOS Robotic Welding, Inc.

911 Albion Ave.

Schaumburg, IL 60193

847-923-9988

info@cloosrobot.com

www.cloosrobot.com