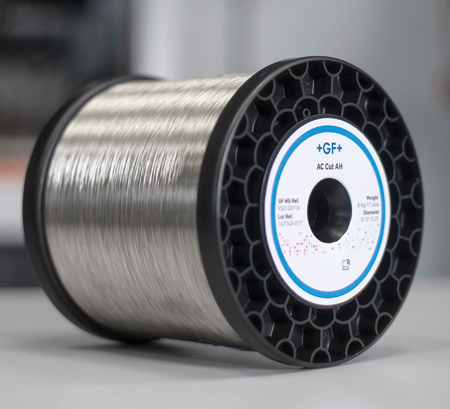

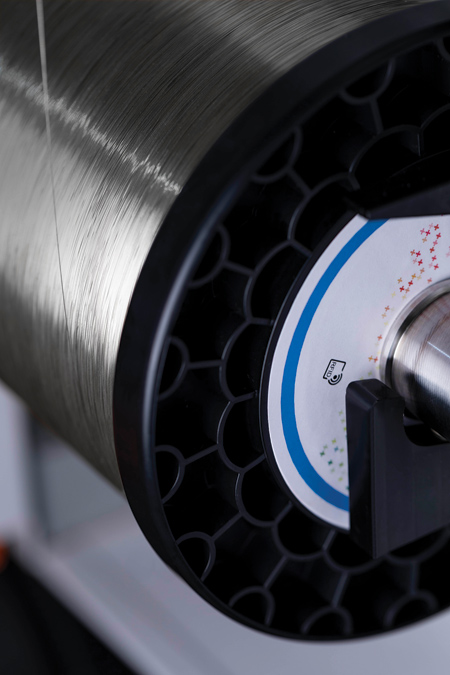

GF Machining Solutions Customer Services' SMART wire stores wire characteristics and traceability-related data with RFID technology, allowing manufacturers to use their AgieCharmilles CUT P series machines to their full potential and achieve Industry 4.0-level process control.

GF Machining Solutions' latest innovations in electrical discharge machining (EDM) includes SMART wire which leverages radio frequency identification (RFID) technology for Industry 4.0-level process control. Specifically aimed at helping manufacturers realize the full potential of their AgieCharmilles CUT P series wire-cutting EDM machines with greater process continuity, traceability and performance, SMART wire demonstrates how the GF division and its Customer Services department is connected to manufacturers' needs.

Process Continuity

Due to SMART wire's monitoring capabilities, the machine operator always knows how much wire is available for the current job. The moment a spool of SMART wire is installed, the CUT P machine recognizes the available length of wire and provides the operator with peace of mind that there will be enough wire on the spool to complete cutting operations without interruptions.

Process Traceability and Enhancement

At the same time, wire traceability is enhanced with SMART wire's ability to provide information such as date of manufacture, type, lot and expiration date, which is transmitted via RFID to the machine report. This advanced traceability is especially important in wire-cutting EDM applications for highly regulated sectors such as aerospace and medical technology.

In addition to the advanced continuity and traceability features, SMART wire users can machine with confidence, as the technology ensures they always use the right wire for the job. For further process optimization, SMART wire checks the wire technology selected on the machine and adjusts the machine performance accordingly for optimized cutting programs.

A SMART Wire for Every Need

GF Machining Solutions Customer Services offers a wide range of SMART wires to help optimize machine performance and improve process continuity and traceability. If the machining priority is surface quality, for example, AC Cut AH 900/500/400 and AC Cut A 900/500 SMART wires are available. To achieve the best productivity, the GF division offers AC Cut VS 900+, AC Cut VS 900/500 and AC Cut D 500 SMART wires. And for those users for whom cutting speed is the top priority, AC Cut VH SMART wire and AC Brass 900/500/400 serve as multipurpose SMART wire solutions.

For more information contact:

GF Machining Solutions LLC

560 Bond St.

Lincolnshire, IL 60069-4224

847-913-5300

www.gfms.com/us