The CPX Linear has the option of the V Steady and Top Roller for tool blanks to provide rigid support and maintain low run out.

The Blank X software guides users through a step-by-step process enabling quick programming for grinding a blank.

The CPX Linear is offered with ANCA's own AR300 low cost loader for automated loading of tool blanks.

"The CPX Linear provides the same strength, rigidity and thermal stability expected from an ANCA tool grinder," said a company spokesperson.

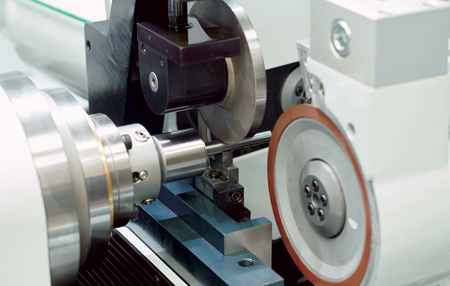

ANCA's CPX Linear is designed with a large working envelope and powerful grinding spindles to achieve high precision and productivity for blank preparation in the market today. "Using the pinch peel method of grinding it offers the same strength, rigidity and thermal stability expected from an ANCA tool grinder," said a company spokesperson.

Simon Richardson, Product Manager at ANCA said, "We have taken the best aspects of our technology to build a fantastic machine. For example, our specially designed polymer concrete base provides the upmost stability in our grinding process so we took that and used it in the CPX Linear model."

The CPX Linear features include:

- High powered roughing spindle ensures high volume stock removal, enabling shorter cycle times and higher productivity.

- Polymer base (ANCAcrete) has enhanced thermal stability and vibration dampening properties, delivering grinding process stability.

- LinX linear motors achieve enhanced precision and performance.

- BlankX software provides ease of use and programming flexibility.

- ANCA motion machine control system - AMC5 CNC and AMD5X servo drives provide all the computing power needed for sub-micron motion control for high accuracy.

- ANCA Motions AR300 low cost robot loader for automated loading of tool blanks is an option.

- Quick set-up times to achieve greater efficiencies.

Powered by LinX

ANCA's LinX linear motor technology for axis motion (X, Y and V axes), in conjunction with linear scales, is designed to achieve enhanced precision and performance. Specially designed for a lifetime of operation in harsh grinding environments, the LinX motors have a cylindrical magnetic field which means there is no additional down force on the rails or machine base.

With no temperature variations (meaning no need for a separate chiller unit), and being sealed to IP67, there is minimal wear and tear so that the machine accuracy remains over the lifetime of the machine. The LinX linear motor has higher axis speed and acceleration, leading to reduced cycle times while maintaining a smoother axis motion.

CPX Linear Capabilities

- With a peak power of 43 kW (58 HP) the grinding spindle for roughing uses a 250 mm (10") diameter wheel, ensuring high volume stock removal in the shortest possible cycle time. This high-powered spindle removes the need for removing material in multiple passes which means shorter cycle times and higher productivity.

- Finishing spindle uses a 150 mm (6") diameter wheel supplying a peak power of 9.7 kW (13 HP) for optimal finish grinding operations.

- Large working envelope with an overall blank length of 360 mm (14.1") and a maximum diameter of 25 mm (1") when manual loading.

For more information contact:

ANCA Inc.

31129 Century Drive

Wixom, MI 48393

248-926-4466

usainfo@anca.com

www.anca.com

Southwest

Keith George

Machine Tool Marketing, Inc.

12345 S. Memorial Drive, Ste. 120

Bixby, OK 74008

918-369-7065

keith@mtmtulsa.com

Mike Koch

Koch Machine Tool Company, Inc.

8500 Westland West Blvd.

Houston, TX 77041

281-720-8500

mike@koch.machinetool.com

Southeast

Chris Miller

Crotts & Saunders

2709 Boulder Park Court

Winston-Salem, NC 27101

336-765-7250

CMiller@CrottsAndSaunders.com

Ken Larson

Southtec Systems, Inc.

18 Wasserman Dr.

Palm Coast, FL 32164

386-864-0453

klarson@southtecsystems.com

www.southtecsystems.com

Northeast

John Nardone

Modern Tools, Inc.

24 Parkway Road

Stoneham, MA 02180

781-438-3211

jnardone@moderntools.com

Vince Smith

Smith Industrial Machine Sales

340 North Creek Crossing

Greece, NY 14612

585-738-8323

smithindmach04@gmail.com

Midwest

Mike Riga

Innovative Machine Solutions, Inc.

227 North Avenue

Watertown, WI 53098

414-333-1343

riga297@aol.com

Bill Beam

Metalworking Technologies Ltd.

2015 S. Arlington Heights Rd., Ste. 122C

Arlington Heights, IL 60005-2132

847-434-1440

wnbeam@metaltechltd.com

Andy Archer

Productivity, Inc.

15150 25th Ave. N.

Minneapolis, MN 55447-1981

763-476-8600

aarcher@productivity.com

Andrew Klavins

Productivity, Inc.

8402 S. 117th St.

La Vista, NE 68128

402-330-2323

aklavins@productivity.com

Dennis Smith

Productivity, Inc.

9440 Atlantic Drive SW

Cedar Rapids, IA 52404

319-632-4288

dsmith@productivity.com

West

James Morton

Machines & Methods

16955 NW Elkton Ct.

Beaverton, OR 97006

503-617-1992

james@mail.machinesandmethods.com

Tony Parr

Machines & Methods

15414 SE 17th Street

Bellevue, WA 98007

425-746-1656

tony@machinesandmethods.com

Clark Smith

Smith Machinery

41 W Guest Avenue

Salt Lake City, UT 84115

801-263-6403

csmith@smithmachinetools.com

Austen Bramhall

Bramac Machinery, Inc. - AZ

27475 Ynez Road, #193

Temecula, CA 92591

951-383-4195

austen@bramacmachinery.com

Martyn Bramhall

Bramac Machinery, Inc. - CA

27475 Ynez Road, #193

Temecula, CA 92591

951-383-4195

martyn@bramacmachinery.com