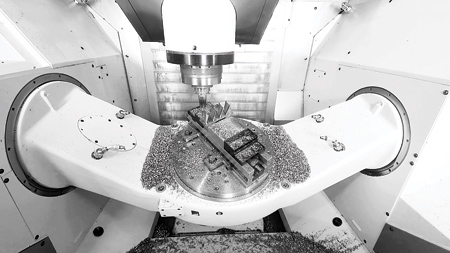

The FZ 16 S 5-axis with 5-axis tilt rotary table is designed to meet the special requirements of the aerospace sector.

"The manufacturing operations for complex precision parts in the aerospace sector require a particularly fast, very precise and extremely dynamic machining center," said a CHIRON spokesperson.

Producing complex aerospace parts such as vanes, blisks and impellers requires a particularly fast, very precise, and extremely dynamic machining center. For manufacturing critical components used in engine and turbine construction, this means a 5-axis machining center. Machines for highly dynamic milling with five simultaneously controlled axes are essential for producing reliable aircraft engine components.

A developer of CNC-controlled vertical milling and turning centers, the CHIRON Group recently brought a machining center to market precisely matched to the special requirements of the aviation sector: the FZ 16 S 5-axis with 5-axis tilt rotary table.

"Optimum solutions for machining complex aerospace workpieces from exotic materials must provide superior rigidity for stable machining; high spindle speeds to make best use of cutting tools designed for shaping challenging metals; and rapid axis positioning to minimize cycle times. The result is production of high precision parts with high quality surface finishes in minimum time," said a company spokesperson.

The mineral cast machine bed of the CHIRON FZ 16, with rigid gantry design, offers a high degree of stiffness and optimum damping characteristics. "High-performance motors, two Y-axis drives, as well as short spindle start-up and braking times are the foundation for the machine's extreme speed," said the spokesperson. "A-axes and C-axes equipped with direct drives deliver even greater dynamics. These machine characteristics assure precise multi-axis motion and smooth acceleration, which are fundamental requirements for high-level aerospace manufacturing."

"A key development for the Chiron machines in providing greater stability for the heavier cuts and the rapid axis positioning is the gantry-style construction rather than a C-frame," continued the spokesperson. "This construction will be seen in future Chiron Group machines. The base is a vibration-dampening, highly stable concrete material that is less sensitive to heat than cast iron or steel weldments. Even during heavy cuts, the machine runs nearly without vibration or noise."

Combining high precision metal removal with high feedrates yields a machine that can hog material while delivering high quality surfaces. "This capability will be of great interest to the pump, compressor, aerospace components, mold and die, and automotive industries that produce complex parts from high alloy and exotic metals such as titanium, Inconel and stainless steels," said the spokesperson. "The ability to produce finished parts rapidly in a single set-up saves cycle time and avoids the need for secondary operations."

"The exotic materials used for aerospace applications present challenging demands for high accuracy machining," said Markus Löhe, Aerospace Sales Engineer at CHIRON. "The complex part geometries and the need for smooth surfaces require 5-axis simultaneous machining capability."

For example, a blisk consists of up to 120 individual blade components on a disk and has a diameter of around 800 mm. Workpieces of this kind can only be consistently produced on a fast, high accuracy machining center, such as the CHIRON FZ 16 S 5-axis.

"Blisks are currently machined on CHIRON machines from Inconel at one of our major customers in the sector, where the new FZ 16 S 5-axis machining center delivered excellent results from the first workpiece," reported Löhe.

Turn-Key Customer Solutions from CHIRON

Turn-key machines are particularly important for the aerospace sector because they reduce handling and therefore promote not only lower cycle times, but higher machining accuracy as well. These complete solutions with end-to-end automation are matched to individual customer requirements at CHIRON. The CHIRON Group generates more than a third of its revenue with turn-key machining centers every year.

In addition to the holding fixture and selecting the most effective cutting tools, the software provided in the turn-key system also makes a contribution to greater productivity and dynamics in aerospace machining applications.

The software systems in the CHIRON SmartLine portfolio make full use of the performance offered by the machining centers. For example, maintenance work and repairs can be planned in a targeted way with the ConditionLine IT system, which allows productivity to be significantly improved. This software detects signs of wear, as well as atypical behavior early on during operations, which helps prevent costly downtimes before they occur. In terms of CNC control systems, customers can choose between Siemens, FANUC or Heidenhain.

To see a video of the FZ 16 in action, visit www.youtube.com/watch?v=oQP0cumxVXE.

For more information contact:

CHIRON America, Inc.

10950 Withers Cove Park Drive

Charlotte, NC 28278

704-587-9526

info@chironamerica.com

www.chironamerica.us

CHIRON America, Inc.

44692 Helm Street

Plymouth, MI 48170

734-233-9650