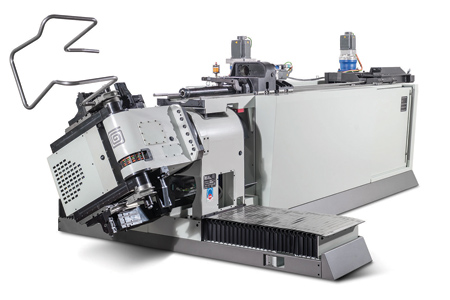

BLM-123: BLM GROUP USA Model E-TURN all-electric tube bender

The E-TURN electric bending system from BLM GROUP USA is suitable for a wide range of applications and can handle complex bends quickly and accurately. "In-process right-hand and left-hand bending, 15 all-electric axes and integrated automatic loading and unloading systems combined with the user-friendly VGP3D programming software ensure production is right from the first part," said a company spokesperson.

Each of the E-TURN's two bend heads for in-process right-hand and left-hand operation can mount up to four tools for creating various fixed and variable bending radii for a variety of jobs without the need to change the tools between each one. The bend head design can apply up to two tons of pressure, making it possible to bend complex radii less than 1-D on tubes ranging from 0.250"- 2.0" in diameter.

All machine movements, including the clamps, are controlled via CNC by means of electric axes for accuracy and repeatability. The tools are calibrated automatically using pre-stored parameters, saving set-up and job changeover times.

Automatic tube loading and unloading are functions included in the E-TURN system operating logic. Loading or feeding systems can be either positioned to the right or left side of the machine. Finished parts can be unloaded by releasing them onto an exit conveyor.

The 3-D visual graphic programming system, VGP3D, is a key element of the E-TURN. The programmer can view a 3-D simulation of the part being created simply by entering the bent tube's geometric data. The software also calculates real processing times and accurately checks for collisions prior to bending the first part.

The E-TURN bending system can be integrated in an all-in-one process with a lasertube system to generate accurate laser cut and bent parts. Data is exchanged between the systems to resolve and correct for the issues inherent to each technology, such as tube elongation caused by bending.

By only drawing electricity when the axes are in use, the E-TURN's energy consumption is less than one tenth of a conventional hydraulic bender. The elimination of the hydraulic system means there is no need to dispose of waste oil and provides a very quiet operation.

"High performance, extreme flexibility and high accuracy mean the E-TURN series of benders can satisfy the demanding requirements of a variety of industries such as: aerospace, automotive, furniture, recreational vehicles and any manufacturing sector in general," said the spokesperson.

For more information contact:

BLM Group USA

46850 Cartier Dr.

Novi, MI 48377-4117

248-560-0080

sales@blmgroupusa.com

www.blmgroup.com