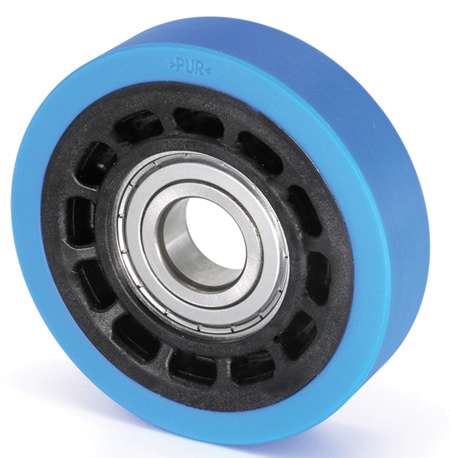

Support and Guiding Rollers

April 1, 2018

Support and guiding rollers from faigle are made of thermoplastic polyurethane which has excellent wear resistance.

"Support and guiding rollers from faigle reliably deliver 15 to 20 years of tough continuous operation with performances of over 65,000 km - even under harsh operating conditions," said a company spokesperson. Applications include sorting plants, conveying systems and warehouse logistics systems.

"The high quality of faigle rollers is due to the PAS-PU material, which was specially developed for these types of applications," continued the spokesperson. "The plastic has excellent mechanical properties including high wear resistance, resistance to humidity and grease and resistance to climatic conditions."

The Austrian manufacturer offers rollers made of hydrolysis resistant polyurethane as protection against hydrolysis, which is the decay of plastic by water molecules. The material has been used for decades as the standard material for all support and guiding rollers from faigle. "When it comes to humidity resistance, they are superior to models made of cast polyurethane. faigle rollers can therefore be used trouble-free, even in regions with high air humidity," said the spokesperson.

The design, material, ball bearings and high-precision manufacturing technique are specially selected to achieve maximum vibration dampening as well as quiet and smooth operation. faigle has an extensive pool of state-of-the-art test stands to offer high quality and includes tests for concentricity, resistance to hydrolysis, start-up and roll resistance and flattening tendency. Short- and long-term running tests supply data on the product's suitability for the intended application and service life.

For more information contact:

faigle Kunststoffe GmbH

www.faigle.com

< back