Semi-Automated Positioning System

April 1, 2018

Standard Interconnect Kit or SIK

Piranha Ironworker Integration with an Advanced Interconnect Kit or SIK

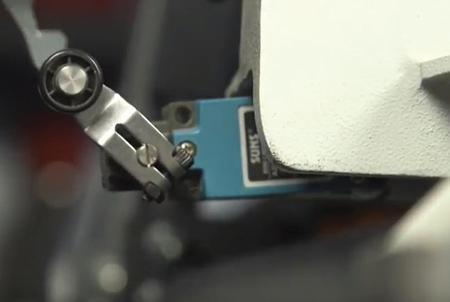

TigerStop has developed a semi-automatic integration kit for the Piranha Ironworker using its patented Standard Interconnect Kit (SIK). The SIK functions as a safety interconnect, preventing the ironworker from cycling while the TigerStop is in motion and offering productivity enhancing benefits by partially automating the punching or shearing process.

The SIK is beneficial in that it moves the TigerStop to the correct dimension within a cut list without the operator having to press start, but the operator is still able to reposition parts before the next punching or shearing cycle begins. "The SIK provides the benefits of increased accuracy and throughput while reducing operator fatigue, but at a lower price point than the fully automatic ironworker integration using the Advanced Interconnect Kit," said a company spokesperson.

TigerStop previously released a fully automatic integration for the Piranha Ironworker using TigerStop's patented Advanced Interconnect Kit (AIK). The AIK facilitates precise control and coordination of movement between the TigerStop and Piranha Ironworker, allowing an operator to simply place stock on a punch or shearing station, download the part list into the TigerStop controller and press start. The TigerStop then moves the stock into position, cycles the punch or shear and moving the stock to the next position until the job is complete.

The AIK saves operators time and labor measuring and marking stock and setting up manual clamps. For those operators who need to remain at their stations, adjusting the depth of material or repositioning parts, the SIK sufficiently completes the job.

The SIK and AIK integration kits for ironworkers are available for many different brands of ironworkers.

For more information contact:

TigerStop, LLC

12909 NE 95th Street

Vancouver, WA 98682

360-254-0661

www.tigerstop.com

< back