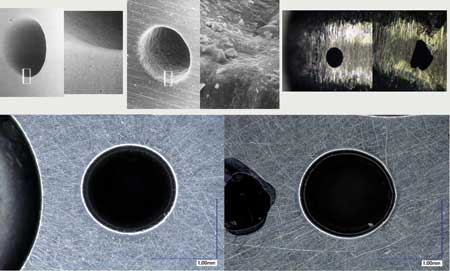

Pictured is a comparison of Kennametal MICROFLOW versus hydro erosive grinding, according to the company.

"Fuel system manufacturers seeking the best fuel performance require flexible high-flow grinding and high-flow test capabilities to achieve finely tuned orifices in numerous design variations," said a Kennametal spokesperson. "To this end, Kennametal Precision Surface Solutions offers EXTRUDE HONE MF PROGRESS, the next generation of flow tuning and flow measurement featuring a flow targeting accuracy to +/-1% aimed at orifices 100-350 um in parts less than 30 mm in diameter and flow rates up to 5 L/min."

"Additionally, MF PROGRESS delivers another exclusive added value that we call Flexibility Through Modularity," said Sharath Shankaregowda, Kennametal Precision Surface Solutions MICROFLOW Product Manager. "Customers benefit from a self-contained modular construction for each process (grinding, flush, flow testing, etc.) and configurable hardware (manifolds, frequency drives, etc.)."

The addition of such advanced process options is designed to help ensure components meet stringent government regulations. "From CAFÉ in North America, EURO6 and expected EURO7 in Europe, and PRC standards in Asia - all focused on reducing CO2 emissions - EXTRUDE HONE MF PROGRESS provides a suitable next step in upgraded manufacturing and finishing," said the spokesperson. "In addition, this all takes place in a 25% reduced machine footprint, 50% less tool wear compared to previous-generation equipment, and depending on the application the output can be increased by up to 100%."

According to the company, MICROFLOW is the real-time monitored flow of abrasive media through small passages, such as fuel-injector spray holes. It achieves specific, repeatable processing results, including edge radius, micro-hole size and surface finish.

"These changes to small-hole geometry improve part function and performance," said the spokesperson. "Media flows in one direction, similar to part operation. Increased flow is attributed to subtly changing the geometry of the opening entrance (opening exit usually is not affected)."

MICROFLOW processing involves pressure drop, flow rate, geometry and fluid properties; machine design and dynamics; workpiece characteristics; media properties and processing procedures. Exclusive range of standard and customized MICROFLOW media with specific properties are designed to perform a step beyond classical hydro erosive liquid.

"EXTRUDE HONE MF PROGRESS is available in various inside station layouts: flow tuning, media reclaim, flush module, test module, marking, due to the system's modular design and construction," said the spokesperson. "It is easy to configure and fit into modern production lines ready for robotic or other handling system automation. The machine also comes with expanded on-screen maintenance capabilities and improved filtration to further pump and valve life.

"EXTRUDE HONE MF PROGRESS also provides for online monitoring and control of all relevant parameters. The online feature is beneficial in delivering remote process demonstrations and gathering resulting data."

For more information contact:

Precision Surfaces Solutions

AFM MICROFLOW Center of Excellence

Kennametal Inc.

1600 Technology Way

P.O. Box 231

Latrobe, PA 15650

724-539-5000

extrudehone.sales@kennametal.com

www.kennametal.com