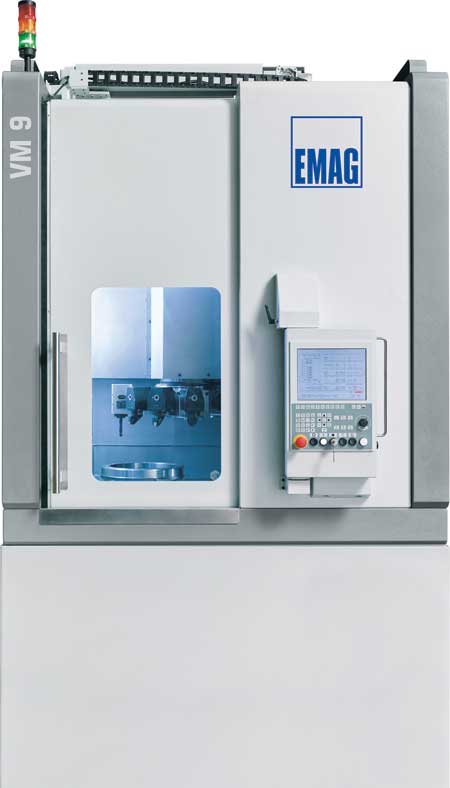

The VM 9 was designed for the machining of chucked components with a diameter of up to 450 mm.

The VM 9, built for machining small series of chucked parts, is ergonomic, precise and productive, according to the company.

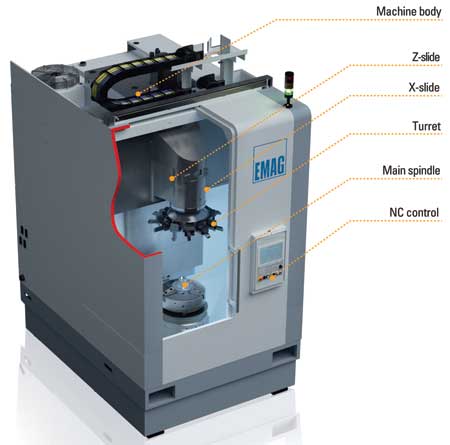

The bottom spindle can hold workpieces with a diameter of up to 450 mm. These are machined by the 12-station disc-type turret which can be fitted with both turning and driven tools.

The VM 9, designed for manufacturing small series at low cost, offers excellent accessibility, according to the company.

"Part of the large family of EMAG modular machines, the VM 9 vertical turning center is designed for the manufacture of individual parts and small production runs with a wide variety of parts, combining a reliable design with an extensive range of equipment," said a company spokesperson. Designed to machine chucked components with a maximum diameter up to 450 mm, it features a tool turret which can be fitted with up to 12 tool positions, depending on the tool interface (BMT or VDI). The turret can be equipped with driven tools to carry out drilling or milling operations.

"The particularly good damping properties of Mineralit, combined with the compound slide with the X- and Z-axes, ensure excellent machining quality, high-speed processes and short idle times," said the spokesperson. "The main spindle provides the necessary power with a 83 kW rating and a torque of 990 Nm, and the integrated probe delivers absolute process reliability by ensuring continuous quality control of the workpieces. Thus, the VM 9 is well-equipped for a wide variety of production tasks, enabling it to produce a wide range of workpiece formats. In terms of ergonomic design, both the machining area and all maintenance components are easy to access."

"This is the positive aspect of the VM 9," said Georg Hndel, Manager Technical Sales at EMAG Leipzig Maschinenfabrik GmbH. "It is an advantage for customers who have to machine many different workpieces as prototypes or various part families in many different manufacturing scenarios."

The VM 9 is suitable for a variety of applications including components for trucks, construction and agricultural machines or mechanical and plant engineering. The excellent accessibility to the machining area makes the machines an all-round solution for turned parts.

Following are some of the technical features of the VM 9:

- Max weight: 300 kg

- Swing diameter over base: 650 mm

- X-axis/Z-axis travel: 330/500 mm

- Main spindle:

- Spindle flange to ISO 702-1: 2009 Size 8

- Spindle bearing 140/160 mm

- Main drive unit:

- Synchronous motor (40% duty cycle): 49 / 83 kW

- Synchronous motor (100% duty cycle): 32 / 54 kW

- Full performance from spindle speed of 800 RPM

- Torque (40% duty cycle): 585 / 990 Nm

- Torque (100% duty cycle): 380 / 650 Nm

- Speed: 3,000 / 2,400 RPM, max.

- Feed drive:

- Rapid-traverse rate X / Z: 30 / 30 m/min

- Feed pressure X / Z: 4 / 8 kN

- Disc-type turret:

- Turret interfaces: VDI 40 / BMT 65

- Turret tool positions: 12 / 12

- Torque of driven tools, 40% / 100%: 24 / 15 Nm

- Speed of driven tools: 6,000 RPM.

Following are some of the benefits of the VM 9, according to the company:

- All the service units are easy to reach

- Axis monitoring by rotary, indirect absolute encoders; all axes with fully encapsulated linear glass scale (optional)

- Generously dimensioned main spindle, maintenance-free spindle motors and rigid guideways.

More information about the VM 9 may be found at http://vm-vmc.emag.com/es/vm-9.html.

For more information contact:

Peter Loetzner

EMAG LLC

38800 Grand River Avenue

Farmington Hills, MI 48335

248-477-7440

info@usa.emag.com

www.emag.com

Southwest

AR

David Fitzgerald

EMAG LLC

248-595-1117

www.emag.com

TX, OK, LA

Ric Lorilla

EMAG LLC

248-595-1530

rlorilla@emag.com

Southeast

VA, NC, SC, GA, FL, TN, AL, MS

David Fitzgerald

EMAG LLC

248-595-1117

www.emag.com

Northeast

PA, NY

Kirk Stewart

EMAG LLC

248-996-4703

kstewart@emag.com

ME, NH, VT, MA, RI, CT, NJ, DE, MD

Jonathan Chomicz

EMAG LLC

248-497-8526

jchomicz@emag.com

WV

David Fitzgerald

EMAG LLC

248-595-1117

www.emag.com

Midwest

IN, MI, OH

Kirk Stewart

EMAG LLC

248-996-4703

kstewart@emag.com

ND, MN, WI, SD, NE, KS, IA, MO, IL

Tod Petrik

EMAG LLC

248-470-2646

tpetrik@emag.com

KY

David Fitzgerald

EMAG LLC

248-595-1117

www.emag.com

West

Peter Loetzner

248-477-7440

info@usa.emag.com

Arnie Sugiyama

Caltec International

19801 Hamilton Ave

Torrance, CA 90502

310-527-4110

arnie@caltecusa.com