New Hybrid Wire Offers Improved Quality and Cleanliness

July 1, 2015

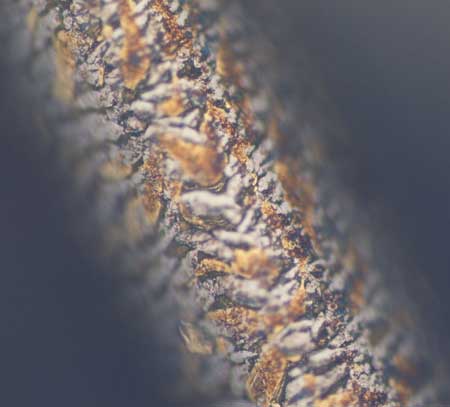

ZT Wire

Brass Wire

"MC Machinery Systems' ZT Wire for EDM machining is especially designed for maximum speed (average 30% higher than conventional brass wire), superior accuracy, surface finish and clean cutting," said a company spokesperson. "The hybrid wire's outer zinc layer is baked on, making it more resistant to flaking than coated wires. This facilitates much cleaner operation and reduces machine maintenance."

The baked-on zinc coating is also designed to add microscopic but precise pockets to the wire's surface that allow more water to integrate into the cutting process. The extra water allows for more efficient cooling in the off-time of the pulse, minimizing electrode breakage and allowing for maximum spark energy during the on-time. "This high spark energy makes faster cutting, superior accuracy and finer finish all possible," said the spokesperson.

The ZT Wire is available in both hard and soft versions, P2 through P15 and K125 through K250 size spools. It also includes MC Machinery's Consumable Products Groups replacement guarantee. More details can be found at www.mcmachinery.com/products-and-solutions/category/consumables/.

For more information contact:

MC Machinery Systems, Inc.

1500 Michael Drive

Wood Dale, IL 60191

630-616-5920

mitsedm@mcmachinery.com

www.mcmachinery.com

< back