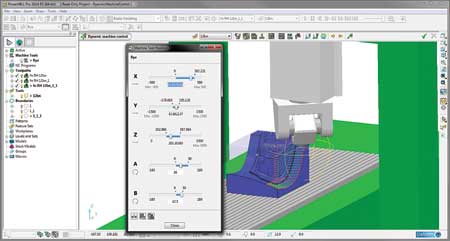

PowerMILL 2014 R2 includes a new dialogue to track the position of the machine tool's components during 5-axis machining

Delcam will demonstrate the 2014 R2 version of its PowerMILL CAM for high-speed and 5-axis machining in booth 1342 at the MFG4 exhibition. The release includes new options to machine parts and tooling with enhanced speed and accuracy. "New simulation and customization tools, plus greater editing flexibility, give even greater opportunities to minimize programming times and reduce manufacturing times," said a company spokesperson.

A series of improvements to Delcam's Vortex high-efficiency area-clearance strategy are also included in the new release. "Vortex gives fast, safe metal removal by allowing solid carbide tooling to cut with its full flute length, minimizing machining times," said the spokesperson. "At the same time, Vortex toolpaths use a controlled engagement angle between the cutter and the part, and so give a more consistent volume removal rate and feedrate, minimizing wear on the cutter. The main enhancement in PowerMILL 2014 R2 improves the ordering of the Vortex toolpaths to minimize lifts and air moves, and so increase overall efficiency."

The most important additions for 5-axis machining are a new dialogue to track the position of the machine tool, and a new toolbar to simulate and adjust the configuration and tool axis of a 3+2 machine or any equipment with incremental rotary axes.

The new dialogue has a redesigned user interface giving improved presentation of data on the position of the machine tool, together with the limits set for each axis. It includes a slider to jog the machine components into position during the simulation and displays a warning if any axis limit is exceeded.

The new toolbar can be used to edit the tool axis and the orientation of the machine tool. This allows quick and easy updates to existing toolpaths with the new parameters. In addition, a new workplane that is aligned to the new axis and orientation can be created for subsequent programming operations.

Another addition that will be especially beneficial for 5-axis programming is a new plug-in for PowerMILL that provides a graph of the linear and rotary axes of the machine during the simulation. Analysis of this graph allows users to locate any potential problems, such as sudden changes in direction or axis reversals that can adversely affect the surface finish. Adjusting the position of the part on the machine and running another simulation will often identify a solution to these problems.

A new method for creating composite curves has been added to PowerMILL that is based on similar functionality within Delcam's PowerSHAPE CAD software. This allows adjacent arcs, lines, curves and surface edges to be merged into one composite curve, and so simplifies 2.5D programming and flowline machining.

The editing of curves has also been improved. It is now possible to insert and edit fillets within a composite curve. In addition, the tangents of a point on a Bezier curve can be modified, allowing more precise tangent editing. The number of points on a curve can also be edited and the points redistributed along the curve.

PowerMILL 2014 R2 has seen improvements made to optimize the raster strategies, giving less fragmented toolpaths, without any overlaps. The software eliminates automatically any small, isolated segments that can leave marks on the part's surface. Removing these short moves also reduces lifting of the tool. Cycle times can be reduced further by minimizing overlaps and so preventing over-machining in those areas.

Drilling has also seen numerous enhancements, including a separate strategy for each type of drilling cycle. New external threading and tapered threading options offer several settings to optimize the strategy. In addition, PowerMILL can scan the part to find any positions where holes intersect, and then allows the break distance, feedrate and spindle speed to be adjusted through the intersections.

In a related development, the recognition, creation and editing of holes has been improved. There is now a dedicated dialogue for hole creation and a second dialogue to control hole editing and hole intersections.

Two new tool types have been added to the range supported by PowerMILL. Barrel tools, which are typically used for the manufacture of blades, are now supported. They allow a small cusp height to be achieved while using a relatively large stepover. The addition of dovetail tools allows easier machining of features such as undercuts and gears, which would otherwise require a series of more complex toolpaths with multiple tool changes.

Finally, two areas for customization of PowerMILL have been enhanced. Firstly, the dialogue boxes for creating custom toolbars have been redesigned to improve their creation and management. The maximum number of custom toolbars has been increased from four to 32 and the ability has been added to export them in an XML file for use on other PCs.

Secondly, a number of commands and functions have been added to allow files to be created and manipulated. These allow files and directories to be copied or deleted, data to be extracted from lists using more succinct expressions, the names of active folders to be determined quickly and easily, and any sequence of edits to be automated, for example within a number of template projects.

For more information contact:

Delcam

877-335-2261

marketing@delcam.com

www.delcam-na.com

MFG4 Booth #1342