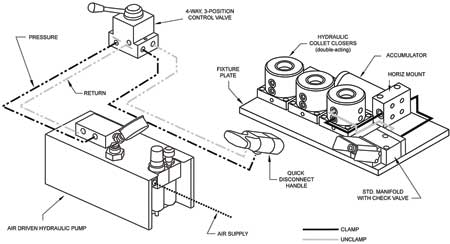

Hydraulic-operated collet block example with quick-disconnect by Hardinge.

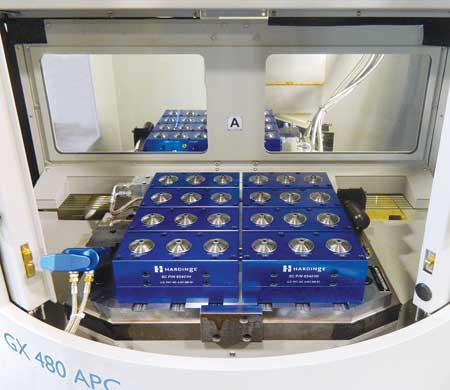

Eight Hardinge TriGrip 5C collet blocks shown with hydraulic quick-disconnect feature.

Collet blocks can be used horizontally or vertically on mill tables, jig grinders, flat or angled fixture plates, tombstones or rotary trunnions. Group them together hydraulically or pneumatically for high-production multi-part machining. Part gripping sizes range from .008" (1C collet) up to 6" (step chuck) in diameter. Hex, square and custom-shaped collets are available to hold a variety of shapes. Hardinge offers several models of collet blocks that use standard collets that may already be used elsewhere in a shop - 1C, 3C, 5C, 16C, 3J, 22J, 35J, and FlexC 42 and 65 mm.

The part diameter or range of parts that a manufacturer is working with will dictate the collet size required. The part size and the machining process to be performed will determine the required gripping force. Higher gripping forces will be needed for heavy rotation, tapping, threading or off-center work. Hardinge can help determine what size collet block is needed, whether a high-force or low-force collet block, and if the need is for hydraulic or pneumatic operation. Clamp only what is required and be sure to operate at the pressure required for each individual machining application.

"Most shops prefer to use pneumatic-operated collet block systems simply because the shop air is readily available and easy to connect, eliminating the need for plumbing accessories. If shop air is not available a small compressor will do the job. Filtered air is always recommended. A simple pneumatic arrangement will consist of a sub plate to mount the collet blocks on and a control valve to clamp and unclamp the part. The operator can use one valve to clamp and unclamp all parts simultaneously or configure multiple valves to control each block or row of blocks independently. Select Hardinge collet block models will plumb together with connector bushings for internal plumbing. Collet block models that don't use connector bushings will have to be plumbed externally.

"Hydraulic-operated collet block systems provide a higher clamping force. A hydraulic collet block arrangement will require a hydraulic source. If you don't already have a hydraulic source at your machine, Hardinge offers an inexpensive air-over-hydraulic pump and accessories for a compact setup. You can use one 2-position, 4-way control valve to clamp and unclamp all parts simultaneously or configure multiple valves to control each block or row of blocks independently. The control valve would mount on the fixture along with the collet blocks and connect to the pump outside of your machine," said a company spokesperson.

A quick-disconnect system is optional. A quick-disconnect handle with standard manifold sets up quickly, but will not maintain the clamp position when removed from the manifold. To maintain the clamped position when removing the disconnect handle, use the manifold with a built-in check valve. This option is suited for preloading pallets. A 3-position, 4-way control valve is required when using the manifold with check valve. An accumulator is recommended and the control valve would be mounted outside of the machine. The accumulator is available in a vertical or horizontal mount and would mount on the fixture with the collet blocks.

"The advantage of machining multiple parts in one setup is huge. The collet block offers advantages over vises and other fixtures. A collet automatically centers the workpiece for reduced setup time. Centers remain fixed when the fixture is removed from the machine table. A collet provides equal gripping pressure around the circumference of the part unlike a standard vise or a 3-point contact jaw chuck. Thin-wall parts or delicate materials may crush or distort in a standard vise or jaw chuck. Sure-Grip expanding collet systems can be used in select collet blocks for internal gripping of the part," said the spokesperson.

Hardinge provides pneumatic and hydraulic accessories to build custom configurations or will custom design and build complete turnkey solutions. "We see collet block applications in the standard job shop for milling, drilling and grinding - but also in the crimping, inspection, testing and assembly environments," said Mike Levanduski, Workholding Sales Manager, Hardinge Inc. Hardinge also manufactures collets, step chucks and expanding collets for use in collet blocks.

For more information contact:

Hardinge Inc. Workholding Div.

800-843-8801

info@shophardinge.com

www.shophardinge.com