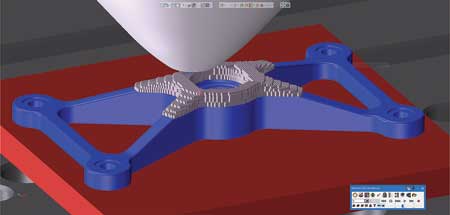

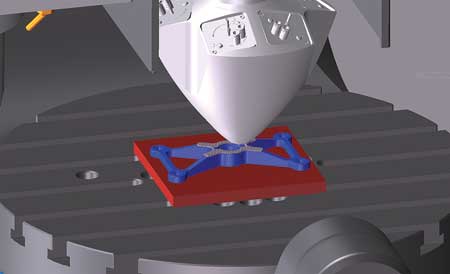

Hybrid machining has many applications, like the example shown here. A worn-down section of an existing part is repaired by directly adding new metal material. Once deposited, conventional subtractive machining-roughing and finishing-provides a smooth surface finish.

CAMCO, the Authorized GibbsCAM Reseller in the Northeast, will demonstrate GibbsCAM at Manufacturing Technology Series EAST (formerly named EASTEC) in booth 5130.

CAMCO will debut the new Hybrid Machining option. This technology combines the power of additive and subtractive machining in a single hybrid machine. The ability to perform additive and subtractive machining operations on a single part has many applications, including printing parts from scratch, rebuilding worn parts, repairing damaged parts, printing multimetal parts and quickly creating prototypes for R&D purposes.

"Advanced simulation capabilities provide visualization of multiple additive strategies as well as subtractive machining for complete confidence in the process," said a spokesperson. "GibbsCAM is one of the first to market with this game-changing technology, which is currently available on Phillips Additive Hybrid machines."

CAMCO will also highlight the new AI features in GibbsCAM 2025. GibbsCAM Copilot is an AI help assistant that provides quick answers to any GibbsCAM question without the need to search through documentation.

A sneak peek of the new up2parts autoCAM for AI-assisted part programming will also be available in the CAMCO booth. This new technology is available as an integrated GibbsCAM plug-in that can automate CNC programming of milled parts and reduce programming time by up to 70%.

Also featured will be the new OptiThreading toolpath strategy from Sandvik Coromant, which gives users better chip control and faster cutting speeds. Other advanced turning strategies include PrimeTurning, which allows users to cut in all directions, and Y-axis turning, which provides better stability, chip control, surface finish and cutting speeds.

For more information contact:

CAMCO

6 Della St.

Ithaca, NY 14850

805-325-3425 / 407-965-6915

sales@camco-ne.com

www.camco-ne.com

Manufacturing Technology Series EAST

Booth 5130