1-Amp Continuous Micro-Sized FlexPro Servo Drives

October 1, 2024

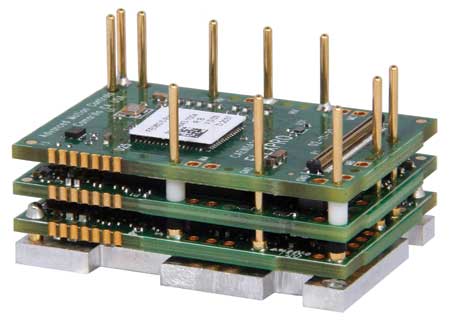

FE060-1-EM-PCB-mount, EtherCAT

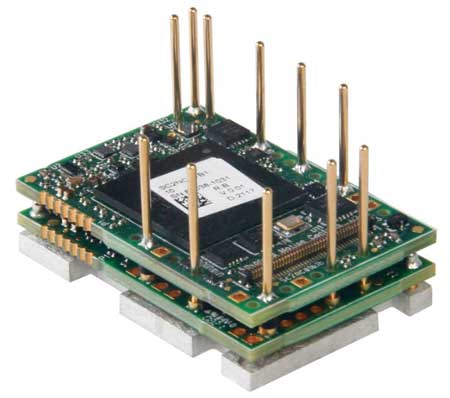

FE060-1-CM-PCB-mount, CANopen

ADVANCED Motion Controls has released the FE060-1-EM and five other 1-amp continuous (RMS) FlexPro servo drive models with high-resolution current control.

When asked to quantify the improvement in current sense resolution of the new servo drives, Mason Karbassian, Senior Electronics Engineer at ADVANCED Motion Controls, said: "In terms of current resolution, if you are comparing an FE060-5-EM drive and an FE060-1-EM drive, the ratio between the peak or RMS ratings will be applicable: 10Ap/2Ap = 5Arms/1Arms = 5x. So, you are looking at a 500% delta in terms of current resolution between the two drives, when used with the same 1Arms load."

Since torque is directly proportional to the current, increasing the current resolution by 500% increases the torque resolution by the same amount. This benefits torque sensitive applications like surgical robots and semiconductor wafer handling where precise torque control is essential to achieve the best results.

The 1-amp FlexPro drives are available in PCB mount and machine embedded form factors. The PCB mount form factor mounts directly to a PCB to achieve the tightest possible integration with the machine. Up to four of these micro-sized models, can fit within the footprint of a business card. Alternatively, the machine embedded versions use traditional cabling and connectors, allowing the engineer to freely install them just about anywhere in a machine.

Features:

- EtherCAT, CANopen, RS-485/232 communication

- 10-55 VDC input voltage

- Rated for 1A continuous current, 2A peak current

- Absolute BiSS C, EnDat 2.2, Tamagawa/Nikon, feedback

- Incremental encoder feedback

- Torque, velocity and position operating modes

- Fully-Configurable loop tuning, I/O, limits, logic and other settings

- Capable of Click&Move embedded programs

- Safe torque off (STO).

Projected industries and applications include surgical robots and semiconductor manufacturing.

For more information contact:

ADVANCED Motion Controls

3805 Calle Tecate

Camarillo, CA 93012

805-389-1935

www.a-m-c.com

< back