New, intuitive HTML-format reports enable users at all levels or expertise to better understand the results of scan-data analyses.

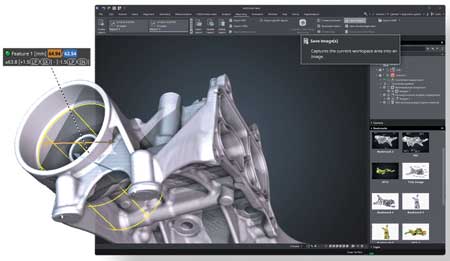

Users can show and share results more easily with new PNG formatting in Version 2024.1.

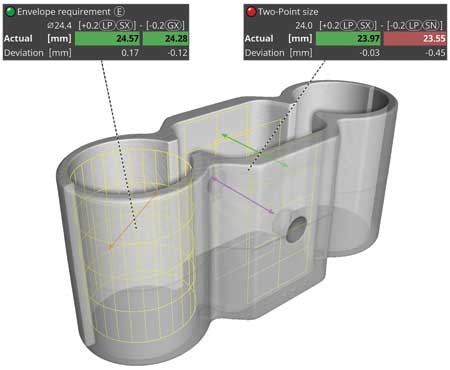

On-screen callouts of industry-standard abbreviations makes it easier to perform GD&T evaluations based on scan data to determine product quality.

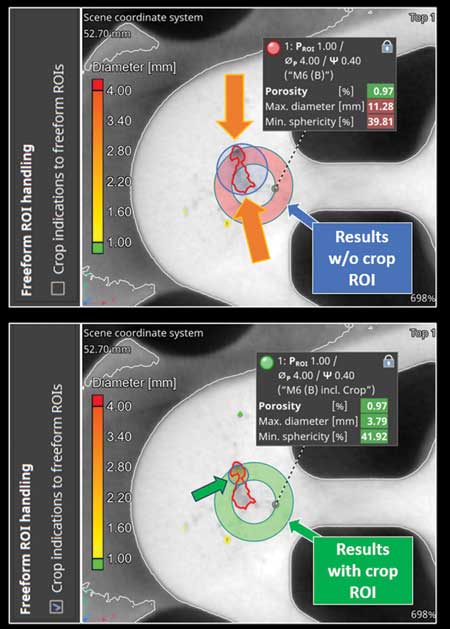

Porosity inclusion analysis (PIA) results are color-coded to show whether pores in a manufactured part are within (or beyond) industry tolerance standards.

The widespread digitalization of manufacturing is enabling companies to make products faster. As a result, the physical inspection of finished goods, based on CT and other industrial product-scanning technologies, has taken on even more importance. As the digital product-development pathway has become increasingly sophisticated, ease-of-use of the accompanying scan data-based quality assurance software is key to its successful application in aerospace, automotive, electronic, medical and other industries.

The newest release of Volume Graphics' advanced nondestructive evaluation software suite responds to this ease-of-use need. With enhanced data interpretation, collaboration and presentation capabilities, the software enables users to more easily refine, integrate and share their product manufacturing quality results and initiatives.

"The underlying architecture of the suite (which includes VGSTUDIO MAX, VGSTUDIO, VGMETROLOGY, VGinLINE and myVGL) harnesses sophisticated algorithms developed over decades, incorporates greater automation and now includes customized, deep learning tools," said a company spokesperson. "The latest updates enable even the nonexpert user to quickly and effectively apply these powerful resources to quality evaluation throughout the product lifecycle-and collaborate with the experts in a common language."

Interactive Reports and PNG Format

Sharing scan data results and reports is a vital part of moving a manufacturing organization forward on the journey towards optimal product quality. Reporting needs to flow from engineers to managers-who may not have run any analyses themselves but want to understand when and/or where a particular pore or crack occurred, and why an accept or reject call was made or a design change implemented.

New in 2024.1 is a highly intuitive HTML report functionality that supports 3D interactive part or result views. Self-contained documents are now easily accessible with any Chromium-based browser like Edge or Chrome, so that analyses can be interactively viewed at any stage of the quality-assurance process.

Along with this, a new PNG export functionality requested by users is available. When using PNG as a storage or data-exchange format, all images produced by Volume Graphics analyses can now be copied and pasted directly into almost any kind of media, without the need for additional file conversions. This change provides for more powerful visualizations, reports and presentations-and a faster workflow for importing or exporting volume data.

Linear Sizes for Metrology

Linear functionality is valuable for users concerned with geometric dimensioning and tolerancing (GD&T). The common abbreviations used to indicate linear sizes are now visually represented directly within report graphics. This simplifies standard conform measurements by providing direct support for modifier symbols and empowers easier evaluations for many size features, such as two-point measurements (LP), envelope requirement (E) and global modifier symbols like (GG).

PIA Updates

Updates in Volume Graphics' porosity inclusion analysis (PIA) capabilities make it even easier for casters to meet industry-compliance requirements P 202 and P 203. Multiple regions of interest can be evaluated to determine whether they are in tolerance or not with instant, color-coded viewing of tolerance states.

For more information contact:

Volume Graphics, Inc.

4944 Parkway Plaza Blvd.

Suite 110

Charlotte, NC 28217

704-248-7736

sales-us@volumegraphics.com

www.volumegraphics.com