Hybrid Range of Tube Bending Machines

December 1, 2021

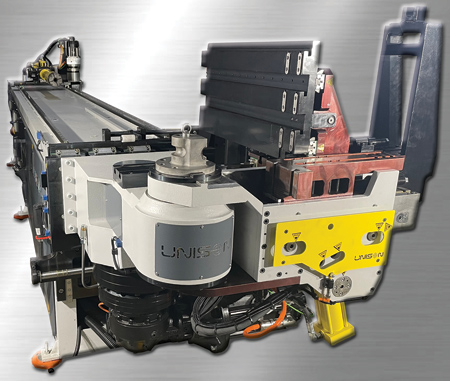

The Unison Synergy HBM (hybrid, multi-stack) tube bending machine

Unison Ltd, a provider of all-electric tube bending machines, has launched a range of hybrid models.

Called Synergy HBM (hybrid, multi-stack), the new machines will initially be available in 50 mm and 80 mm (maximum tube diameter) versions and will feature the company's latest Unibend Lite control system.

"In developing the Synergy HBM range, our objective was simple: to offer all the values associated with the Unison brand to a greater number of tube manipulation businesses," said Alan Pickering, Unison Ltd Managing Director. "The new Unison Synergy HBM range will provide a lower cost entry point for businesses that do not require the extensive capabilities of our all-electric premium range of Unison Breeze machines."

As hybrid machines, Unison's Synergy HBM range combines electric and hydraulic operation. Like the Unison Breeze machines, each model offers enhanced power and rigid mechanical design. Bend arm, carriage, plane of bend and carriage side shift are servo driven, while mandrel, pressure die and clamping system are hydraulically controlled. This makes Synergy HBM machines suited to high volume, repetitive tube manipulation operations that do not necessitate the rapid set-up times and all-electric control provided by Unison Breeze machines for right-first-time repeat sub-contract work.

"Each Synergy HBM machine is equipped with our user-friendly Unibend Lite control system with touchscreen, 3D component simulation and measuring machine interfaces," said Pickering. "We have used Eaton hydraulics, Yaskawa motors and drives and our own Unison tooling mounts. Additionally, the Bendpro CNC control system can be specified as an optional extra by customers in the USA."

For more information contact:

Unison Tube LLC

500 Cane Creek Pkwy.

Ringgold, VA 24586

828-633-3190

sales@unisonltd.com

www.unisonltd.com

< back