Intuitive Control for Improved Productivity

December 1, 2021

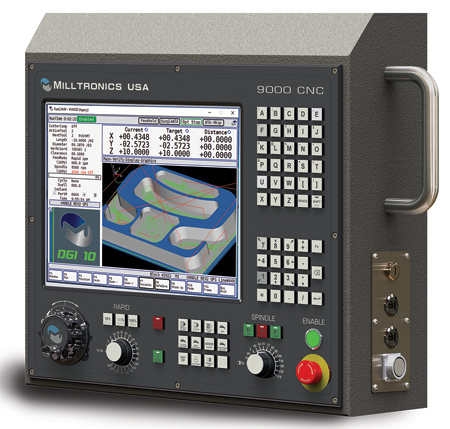

The Milltronics 9000 Series control features 120 GB disk storage, 4 GB memory, up to 10x better graphic performance, mid-travel tactile keys and a large 15" LCD touchscreen. The Windows-based platform offers all the user-friendly features that Milltronics customers expect, such as the G-code visualization screen.

"At Milltronics, we are constantly refining our control to simplify operation, shorten set-up times and provide features that reduce cycle times," said a company spokesperson.

The 9000-DGI Series control features 120 GB disk storage, 4 GB memory, up to 10x better graphic performance, mid-travel tactile keys and an enlarged 15" LCD touchscreen. It is a Windows-based platform and offers all the user-friendly features that Milltronics CNC controls are known for, such as the G-code visualization screen.

"With easy programming, on-screen help, intuitive menus, color graphics and prompted tool settings, the Milltronics 9000 Series control helps new operators train faster and become more productive sooner," said the spokesperson. More advanced operators appreciate features that allow quick and confident operation of the CNC."

Features that allow quick operation of the CNC:

- Solid model graphics allow the operator to see a completed part prior to cutting.

- Mid program restart allows the operator to start anywhere in a program by verifying the graphics and then switching to Run Mode. No need for G&M code expertise.

- Handwheel run allows the operator to run a program in a controlled mode where motion only occurs while the handwheel is turning. This feature allows operators to verify programs with total control.

The 9000-DGI CNC features a dual-core processor and high-speed motion control that is capable of executing 3,000 blocks per second. Operators can run parts programmed conversationally or tool paths generated by a CAM system.

For more information contact:

Milltronics USA, Inc.

1400 Mill Lane

Waconia, MN 55387

952-442-1410

info@milltronics.com

www.milltronics.com

< back