Progressive Die Tapping for Fastener Industry

December 1, 2021

Zagar 128-spindle gearless tapping machine with CNC controller engineered to provide progressive die tapping for the fastener industry

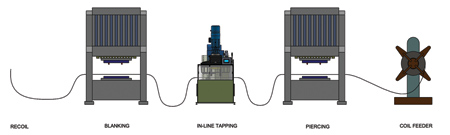

Zagar Inc. offers a gearless multi-spindle tapping machine engineered as an in-line solution that provides high-production tapping of clip and cage nuts for the fastener industry. The CNC-controlled tapping machine provides the central step-precision tapping-for progressive die tapping that also uses coil feed, piercing and blanking.

"The Zagar machine places 128 spindles precisely and very close to center," said a company spokesperson. "A unique gearless drive is key to making it happen, not only getting each spindle as close as possible, but ensuring rigid performance to avoid backlash. The result is high-quality threads with no lag or out of tolerance thread forms due to gear train play that can occur using a geared head."

The process is totally automated and takes place while the clip and cage nuts are still on the strip-in fact, before any operations have been performed. The material is fed off the coil with a precise amount of lag. Then a punch press pierces the material to begin to form the first group. The in-process material is then pulled into the multi spindle tapping machine where all threaded holes are produced in one pass, then onto a blanking press where finished pieces are punched out. The feed is continuous, with a precise amount of slack between stations, so each time the material is positioned, all three operations are performed simultaneously. The process produces from two to 128 fasteners every 10 seconds.

For more information contact:

Zagar Inc.

24000 Lakeland Boulevard

Cleveland, OH 44132

216-731-0500

sales@zagarinc.com

www.zagar.com

< back