The new SUHNER SUNmic 60 micro motor drive system

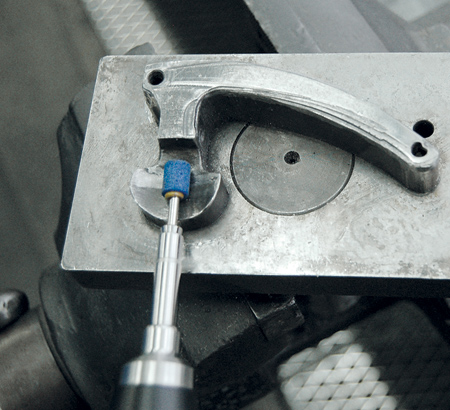

The SUNmic 60 micro motor system has been designed for complex milling, grinding, brushing and polishing work in tool and moldmaking; in aircraft, engine and motor building; and similar applications.

Together with the brushless BL/DC motors, the hand pieces are designed to deliver maximum performance. They offer high concentricity and low vibration.

SUHNER offers an innovative grinding, milling and polishing system, the SUNmic 60.

The central element is an intelligent control unit with touch panel that can accept a range of micro motors and tool hand pieces depending on the application. The control part has modern features such as touchscreen operation on a glass display, the option to save settings and a rotation speed regulator with tangible resistance. Key settings are easily legible on a large digital display.

Micro Motor System

"The actual tools are driven by powerful micro motors whose 280 W place a lot of power in the user's hand," said a company spokesperson. The compact, brushless BL/DC motors provide a wide speed range of 1,000-60,000 RPM and deliver a high torque. "In practice, they can be compared with pneumatic technologies but do not need a compressed air supply, operate at lower energy levels and emit virtually zero noise, without exhaust air or oil mist emissions," said the spokesperson.

One further benefit is that they run virtually free of vibration. The high concentricity safeguards clean and reproducible results in all areas of operation. A special heavy-duty clamping system prevents the millers from shifting. Chuck diameters range from 2.35, 3.0 and 6.0 mm to 1/8" and 1/4".

Flexible Applications

The SUNmic 60 micro motor system can be connected to a 90-240 V source and can therefore be used anywhere in the world. It offers a large number of combinations. The tools range from straight, angle and filing hand pieces to belt grinders. The control unit can be connected to two BL/DC motors and an AC motor and is compatible with available micro motors.

The system can be used everywhere a precision finish is desired: grinding, milling, brushing and polishing in tool and mold making; in aircraft, engine and motor building; in engine tuning; and much more.

SUHNER offers a range of matching machines, tools and abrasives that have been tailored specifically to each of these applications.

SUNmic 60 features:

- Robust control unit with intelligent features and uncluttered digital display

- Touchscreen operation on glass display

- Rotation speed regulator with tangible resistance

- Two sockets for hand pieces with BL/DC motors and one for conventional motors with carbon brushes

- Separate, nonvolatile rotation speed memory for each connection

- Wide, continuous range of rotation speeds of 1,000-60,000 RPM

- High torque

- Low-vibration running and noiseless operation

- High concentricity of 0.01 mm

- Manual and automatic workpiece clamping under high forces

- Overload protection, dust and spray water protection

- Option for connecting a pedal.

For more information contact:

Suhner Industrial Products, LLC

Hwy 411 S. / Suhner Drive

P.O. Box 1234

Rome, GA 30162

706-235-8046

abrasive.usa@suhner.com

www.suhner.com