Soraluce Performance Line TA-Series Bed Type multitasking machining center

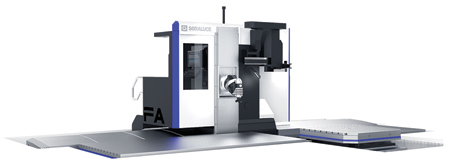

Soraluce Performance Line FA-Series Floor-Type multitasking machining center

Soraluce Performance Line SA-Series Traveling Column multitasking machining center

Soraluce offers its all new Performance Line, a range of universal and multitasking machining centers for medium to large workpieces. Performance Line features three families of machines, with three different architectures, all based on a common modular structure.

Each of the three families of machines that make up the Performance Line include several models and configurations that can be configured for a wide range of applications. These families share major machine features, such as the column, saddle, ram and heads, built on the principle of modular design, to provide reliability, ease of maintenance and flexibility to be adapted to customer needs.

The Performance Line is a rigid and dynamic solution featuring a combination of a cast iron structure, linear guiding systems together with passive and active damping technology. It features a direct drive inline spindle motor with high power and torque located in the ram, with a water-cooling system for the enhanced thermal stability and high precision. The inline spindle motor has continuous power of 32 kW (43 HP), with a current maximum of 7,000 RPM.

The Performance Line offers a new choice of milling heads.

High performance automatic-rotation mechanical heads feature high RPM and high precision that are air-oil mist or water-cooled for maximum head stability and precision.

Universal Heads are available with a choice of indexing: 2.5° x 2.5° / 1º x 2.5º / 0.001° x 0.001°; and compact-design orthogonal heads with indexing of 1º x 1º, providing maximum utilization of machine travel.

For multitasking versions with milling, turning and grinding capabilities, Soraluce designs and manufactures a similar range of high-torque multitasking heads in-house.

Soraluce Performance Line machines can be integrated with a single axis vertical high-speed head providing continuous positioning by torque motor (C-axis) for 4 or 5 axes continuous machining.

Performance Line machines feature a 24" touch-sensitive screen and a larger workspace, providing operators with improved ergonomics and interactivity. In addition to the standard HEIDENHAIN TNC 640 control, machines can be fitted with the latest HEIDENHAIN TNC7 with its new operator interface to make the control system easier to use and boost operator interactivity.

The range features the Soraluce Smart HMI, a smart intuitive interface enabling Soraluce to manage the work area running the NC program in parallel with an area for the development of apps that allow Soraluce to connect the machine to the customer's ERP, or monitoring energy consumption, for example.

New TA, Bed Type Milling Machine

The new Performance Line builds upon an existing machine in the Soraluce portfolio, specifically the TA-A bed type milling machine.

Soraluce has boosted the efficiency of this range and redesigned with improved features that include a new inline spindle drive system, increased RPM, new water-cooled head options, increased rapid feedrates, damping pads, grease lubrication and greater precision.

"The new TA is a milling machine offering greater capabilities than typical machining centers in terms of capacity, power, torque, chip removal and ergonomics," said a company spokesperson. There are several versions or configurations available, including the option of a square or round table, as well as multitasking capabilities.

The machine features standard peripheral guarding with easy front and rear access to the work area. A flexible control panel arm allows the CNC controller to be positioned at the front or rear of the machine, offering the operator the best view of the cutting tool in all machining operation.

This range is floor-fitted and does not require any elaborate foundation.

New FA, Floor Type Boring Mill

When additional longitudinal (X-axis) travel is required, the floor type architecture offers a solution.

The FA is a versatile family of milling machines available in multiple configurations, with a work area tailor-made to the customer's needs for maximum productivity.

FA milling machines can be configured with floor plate, rotary table or rotary-travelling table, with one or more multitasking tables (milling and turning), and with a portable rotary table that can be positioned vertically (with a tailstock) or horizontally. Customers also have the option of duplex configuration, which allows machining with two spindles simultaneously.

Floor type milling machines feature a minimal footprint with a compact design, allowing for multiple work zones when using pendulum machining.

The new FA is designed in such a way that it can be set up either with a pit or at floor level, and the floor plate or worktable can even be raised to the level of loading/unloading offering similar ergonomics of fixed-bed machines.

New SA, Fixed Table Travelling Column Milling Machine

The new SA offers a fully enclosed travelling column design with integrated chip removal systems to keep workshop spaces clean.

The SA family features a traveling column and fixed table that share the same base. The work area is fully guarded, with complete front access to the workpiece, workpiece at user height, a CNC controller on a sliding guide in front of the machine and integrated swarf collection system.

SA machines are available in a wide range of configurations, including a fixed table, rotary milling or milling/turning table of O1,000 mm (39") on one side of the table, or two milling or milling/turning tables at either end of the machine.

Like the FA family, SA machines can operate in pendulum mode. This range is floor-fitted and does not require any elaborate foundation.

Select Machining Technologies (SMT) is Soraluce's U.S. partner offering local expertise, service and parts support. SMT's distributor channel includes full-service distributors Morris, Hartwig, Gosiger and Arizona CNC.

For more information contact:

Doug Schulte

Select Machining Technologies

910 Day Hill Road

Windsor, CT 06095,

256-508-0805

dschulte@selectmachiningtech.com

www.selectmachiningtech.com