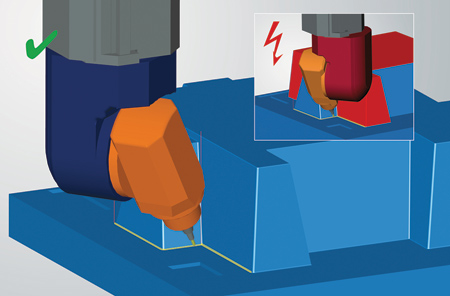

hyperMILL VIRTUAL Machining Optimizer analyzes entire machining sequences and considers axis limitations. Photo shows an example of using Virtual Machining Optimizer with asymmetric head resulting in no collision, compared with not using it and having a collision result.

OPEN MIND Technologies will be highlighting the advanced capabilities of its latest hyperMILL CAD/CAM software suite at WESTEC booth 3121 located at Long Beach Convention Center in Long Beach, CA, from November 7-9, 2023.

"Highly productive programming and machining strategies in hyperMILL enable accurate, efficient 2.5D, 3D, precision 5-axis and mill/turn machining," said a company spokesperson. Attendees will learn about the latest hyperMILL CAM strategies for digital twins and real-time simulation via virtual machining, as well as automation capabilities, additive manufacturing (AM), real-time data sharing and more.

hyperMILL VIRTUAL Machining provides postprocessing and G-code simulation, including a VIRTUAL Machining Optimizer that improves toolpaths that are traditionally calculated in the CAM engine. The Optimizer also incorporates knowledge of the part model, tooling, the toolpath calculation and collision check engine and the machine tool model (digital twins) with its physical constraints. New, improved linking logic in hyperMILL VIRTUAL Machining Optimizer for 5-axis table-table machines will be highlighted. The VIRTUAL Machining Optimizer module links individual part programs by automatically calculating smooth and safe connections between a retract move and subsequent insert, including optimization of clearance planes.

Attendees can also see a hyperMILL VIRTUAL Machining capability for AM processes, where machines often have limited axis ranges. The hyperMILL VIRTUAL Machining Optimizer can be used during NC code generation to simulate and optimize additive tool paths.

The ADDITIVE Manufacturing technology offers flexible strategies for additive material applications on additive machines, hybrid machines (additive and subtractive on one platform) or robotic delivery systems. The additive techniques include filling strategies for planes and free-form shapes in 2D or 3D sections. Applications include creating new components, repairing damaged components or adding features to an existing component, or cladding layers for surface hardening with similar or dissimilar materials.

A hyperMILL Automation Center allows users to automate job list creation processes in hyperCAD-S, and is available as a development or runtime environment. New features also include the ability to select and position a clamping device, as well as define a uniform process for all programmers.

Supporting industrys critical data sharing initiatives to achieve a streamlined flow of information resulting in significant productivity increases, hyperMILL CAM software provides an interface for connectivity to systems that handle manufacturing-relevant data. Attendees will learn how to strategically and automatically load CAD data, and feed CAM data and NC codes back into data-handling systems such as various Product Lifecycle Management (PLM) systems and more. hyperMILL also imports tool data from various manufacturers to create 3D tool data and technology parameters for true-to-detail simulation. Tool data connectivity is helpful for inventory control and more.

For more information contact:

OPEN MIND Technologies USA, Inc.

1492 Highland Ave., Unit 3

Needham, MA 02492

888-516-1232

info.americas@openmind-tech.com

www.openmind-tech.com

WESTEC Booth 3121